Beta transmission is the most common principle for gauging basis weight, and suitable for almost every application. It is often used for coating & converting processes in textile finishing, nonwovens, film extrusion, sheet extrusion, calendering processes and on other coated materials. Precise measurements on moving webs are the result of using extremely efficient beta radiation detectors. Depending on the requirements, different isotopes are available for different applications.

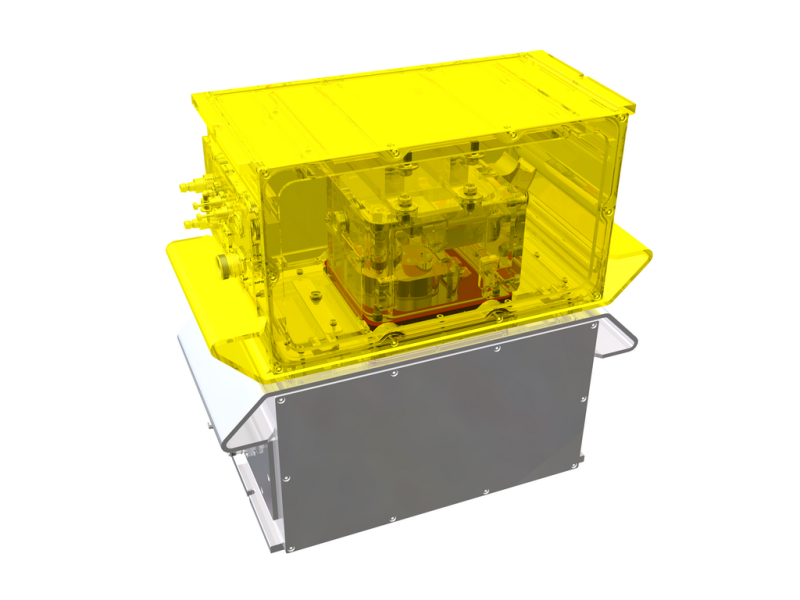

Principle of beta transmission

Principle of beta transmission

The intensity of beta rays is weakened according to the mass of the penetrated layer. Some beta particles get through the material, some particles are stopped. This weakening allows gauging the basis weight of nearly all materials. Different isotopes (Krypton, Strontium, Promethium) are used for different weight ranges. In coating processes, several beta gauges can be used to record the application quantity as a difference in weight.

Except for very low weight ranges, beta transmission is the universal method for measuring basis weight. However, certain radiation protection requirements must be complied with due to the weak radioactive isotopes. The density of the product web can also be determined by beta gauges in combination with thickness sensors. However, is the density of the measured product known and remains constant, the material thickness can also be determined via the basis weight by the beta gauge alone.

Nonwoven hygiene products

KARWEB NONWOVENS, based in Turkey, is one of the big global players in the sector of hygiene products with more than 270 product types made from nonwoven fabric. They export 80 percent of our production to 36 countries, like America, England and Italy. At their Spunlace plant, they can produce protective products against bacterial due to sophisticated technologies like Ozone Threatment and UV systems.

In the quality control process, which is of great importance in the hygiene sector, they rely upon the quality control system Qualiscan QMS-12 from Mahlo. With instant quality detection, they can continuously control the correct component mixture of their fibre products.

A traversing scanner (o-frame) of type Webpro M with two sensors for simultaneous measurement is used for the task. The infrared sensor Infralot IMF detects the moisture. The Gravimat DFI beta sensor measures the basis weight.

Pictures courtesy of Selçuk İplik, Turkey

Gravimat FMI/DFI

Measurement of basis weight (mass per unit area) / thickness /density

Transmission of beta rays

The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The measurement is based on the attenuation of rays from a radioactive isotope through the substrate located in the measuring gap. This attenuation in intensity is an indication of the weight of the product.

The Gravimat uses a target weight to reduce the range of different m2 weights and thereby ensure a more consistent product.

Product Highlights

- Intelligent sensor with ultrafast microprocessor for preprocessing measurements

- Precise measurements as a result of using extremely efficient beta radiation detectors

- Four temperature-compensation sensors along with air pressure compensation

Customer benefits

- Non-destructive, continuous determination of the weight per unit area of product webs

- Highly stable and accurate measurement along with a minimum need to calibrate

- The DFI allows wider measurement gaps and avoids damage to soft webs or wet coatings

The Mahlo Gravimat DFI (Dynamic Flutter Independent) beta sensor uses a revolutionary new sensing technique that allows:

- Complete insensitivity to web flutter throughout the entire measurement gap

- The smallest beta sources and the highest measurement performance

- Very fast scanning speeds with ultra-narrow web defect detection

- Long-term trouble free, cost effective operation in the harshest environments.

Problems with product flatness exist with almost all treatment methods for product webs. Cast and rolled film as well as rolled sheet metal exhibit ripples and flutter, triggered by tension changes, electrostatic charges or band vibration. Paper and coating converters must deal with faulty substrates, edge curl and unsupported product web areas. Manufacturers of nonwovens and fabric are facing fluctuations of degree of drying, density and thickness of their product webs, caused by changes in centre of gravity.

All of these conditions result in measurement errors with traditional transmission sensors like X-ray or beta gauges. Backscatter sensors like gamma or X-ray are even more sensitive to web movement and some are even required to contact the web!

The Mahlo patented DFI Beta Sensor is not affected by web flutter, passline change, ripples, sag or edge curl. The DFI measures accurately throughout changes in loft, density or thickness.

| Specification | Value | Unit | ||

|---|---|---|---|---|

| Type | DFI | FMI | ||

| Isotope | Krypton-85 (Kr-85) | Strontium-90 (Sr-90) | Promethium-147 (Pm - 147) | |

| Measuring range 1 | 10 - 1400 | 100 - 6000 | 2,5 - 160 | g/m² |

1) Referring to PET

Documents