Distortion correction

Weft straightening is crucial for the textile finishing industry

Every one of us has probably owned a pair of trousers where the trouser legs have always been twisted. An annoying phenomenon, which is due to the inferior quality of the material from which the trousers were made. The fabric was distorted.

The order of the weft and warp, knitted courses and wales, rows of tufting or sewing threads give the textile the structure and character that should be retained through all stages of production. Distorted fabrics cause problems throughout the entire production chain. Fabric distortions mean reworking, complaints, rejects and returns. Fabric distortions cost money. Distortion detection and distortion correction are therefore crucial for a trouble-free production process.

No matter whether you work with sensitive, flexible textiles or wide, heavy and stiff materials such as carpets: Orthopac straighteners can be individually adapted to the application. Mahlo's products range from pure sensors for distortion detection to complex, automatic straightening systems, individually configurable and equipped with process control systems.

Better product quality, straight-thread goods and saving resources in a single step: With the Orthopac straightening and process control systems from Mahlo.

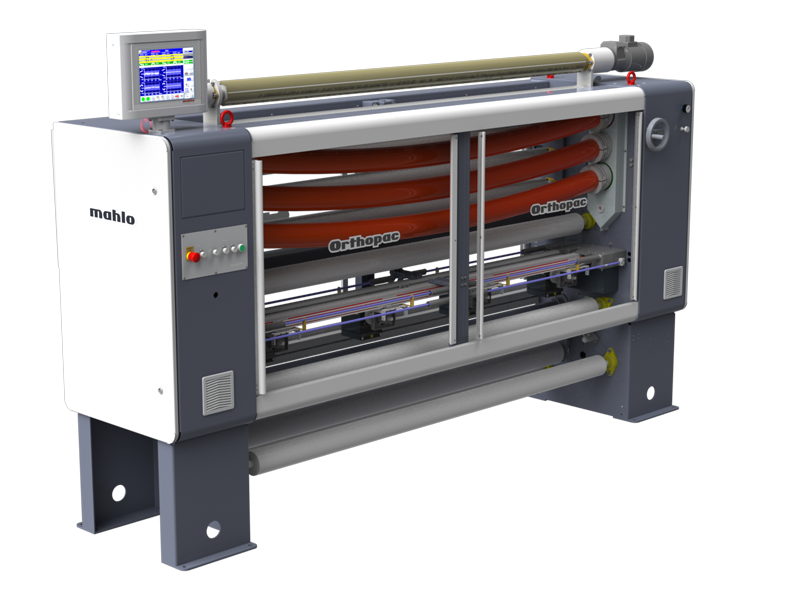

Orthopac RVMC-15 Bestseller

Classic optical weft straightener

Weft straightening the way it should be ...

The Orthopac RVMC is the universally employable straightening system from Mahlo for the correction of fabric distortions for nearly all applications.…

Show details

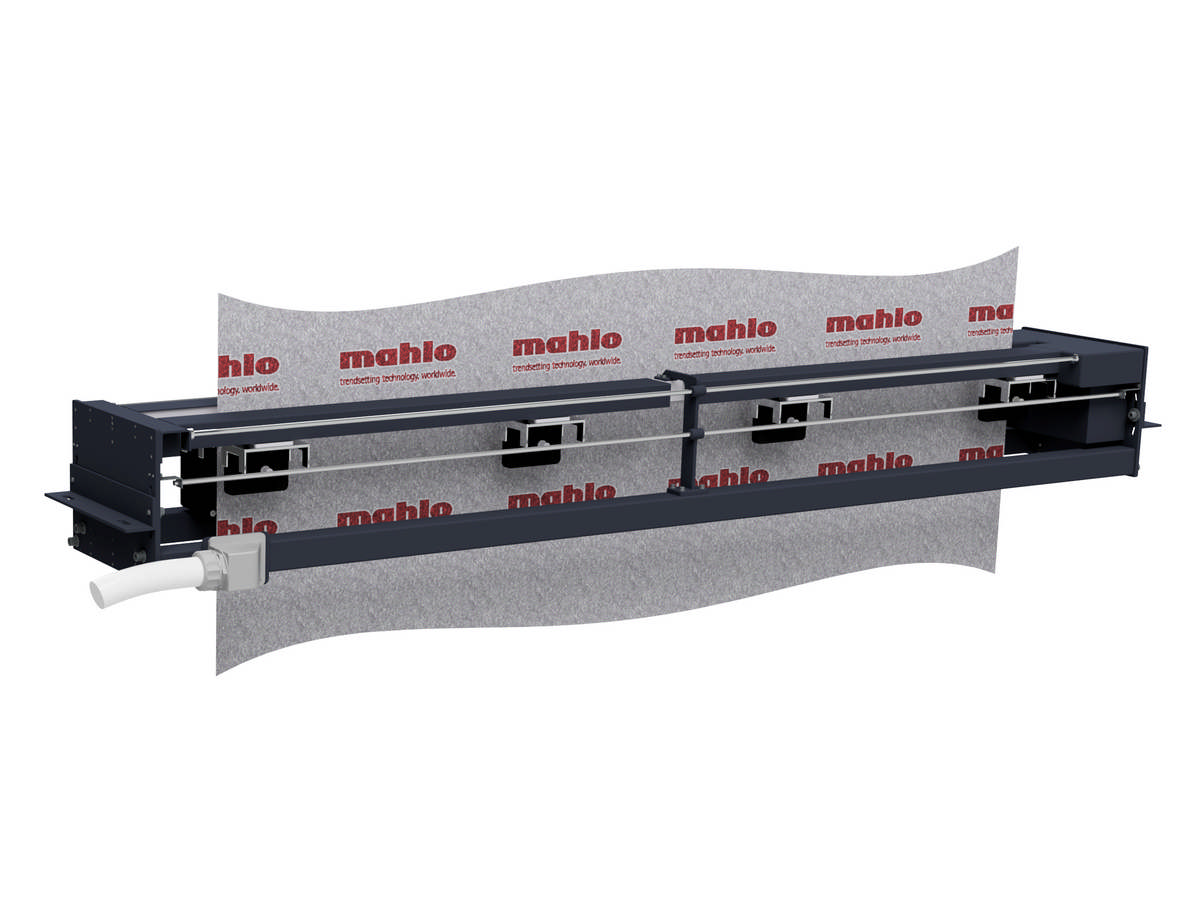

Orthopac FMC-15 Bestseller

Distortion control system

Bow and skew detection and control

The Orthopac FMC automatic straightener is the heart and core of the Orthopac. The device consists of an optical scanning system and electronic control for…

Show details

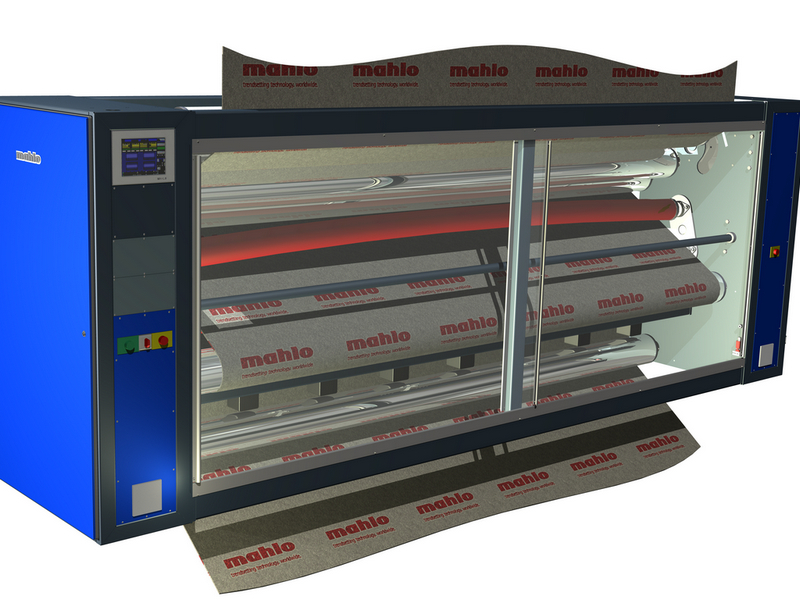

Orthomax RFMB-15 Bestseller

Fusion of pin wheel and roller straightening

Removing all types of distortions

The fusion of pin wheel and roller straightening technology perfectly combines the advantages of both technologies and provides amazing straightening results.…

Show details

Orthopac MFRC-15

Fine tune straightener

Fine-tune straightening of residual distortion

This model represents a compact fine-straightening system for the correction of residual distortions. The special strength of the Orthopac MFRC is…

Show details

Orthopac GMFRC-15

Heavy-duty fine tune straightener

Fine-tune straightening for heavyweight fabrics

The special strength of the Orthopac GMFRC is the extremely high straightening accuracy at relatively small distortions. Thanks to reinforced…

Show details

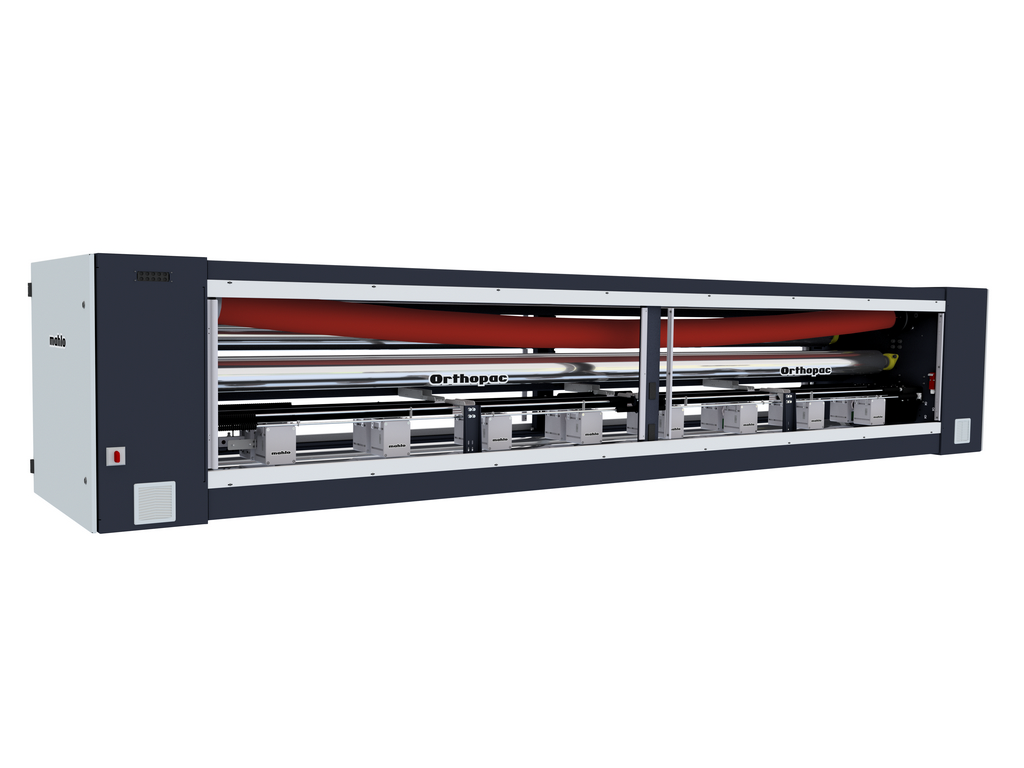

Orthopac GRVMC-15

Modular straightening and process control system for heavyweight materials

Heavy-duty weft straightening

The heavy duty version. High demands due to large product widths (e.g. carpet) or dimensionally stable textiles with defined skew settings (e.g. denim) require a…

Show details

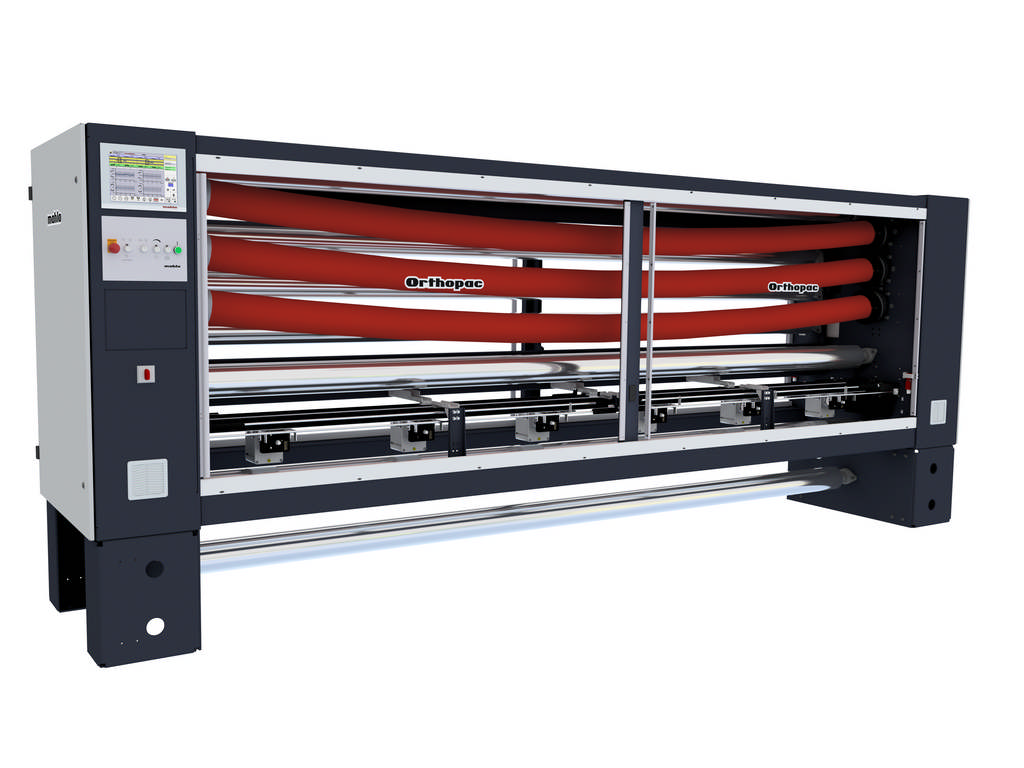

Orthopac CRVMC-12

Special weft straightener for carpets and technical textiles

When the going gets rough ...

The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide…

Show details

Orthopac RXVMC-20

High-end straightening and process control system

Precision straightening machine

Control and actuation at the same time: The Orthopac RXVMC is the only straightening system worldwide to offer this unique combination. This completely new…

Show details

Orthofact RMB-15

Automatic pin wheel straightening system

Removing irregular distortions

Asymmetrical distortions (wavy, S-shaped, etc.) in textiles have always represented a huge challenge in the textile industry. A special straightening approach is…

Show details

Distortion correction

Key task in textile finishing

The production of high-quality textiles requires equipment that monitors critical parameters to maintain speed and quality of the production. Controlling and minimizing distortion in a finishing process is one of the key tasks of a weft straightening system.

Unwanted distortion is usually caused by uneven distribution of tension across the fabric web. The first step to a perfectly straightened web is the determination and analysis of the distortion. This data is then used to control a weft straightener, which corrects the measured skew and bow distortion.