Process control

Measuring, logging and controlling the production process

The business field of manufacturing or converting textiles is increasingly affected by rising costs for production and energy as well as growing demands on quality and flexibility. At the same time, however, profit margins are decreasing and shorter production times are demanded. Efficient, quality-oriented production is therefore essential for successful manufacturers. The use of process control is one of the most important keys to balancing the demands of economic, sustainable and at the same time high-quality fabrication. With life cycles of 20 - 30 years, energy savings and the "Total Cost of Ownership" (TCO) play a decisive role in economic efficiency.

Process control increases efficiency and production throughput, improves quality standards sustainably and verifiably, saves resources and costs, reliably logs tolerances and production data and makes them usable.

Versatile process control systems

Modular design for a wide range of textile applications

Mahlo's portfolio includes a broad variety of process control systems and sensors for any application in the manufacturing or finishing process in the textile industry and related industrial sectors. The short payback times, high reliability and ease of use of process control equipment result in increased productivity combined with a noticeable reduction in waste. Our selection of sensors can meet almost any manufacturer's requirement. The modular design of the system allows flexible adaptation to all applications.

The system measures, logs and controls critical process parameters across the entire working width such as:

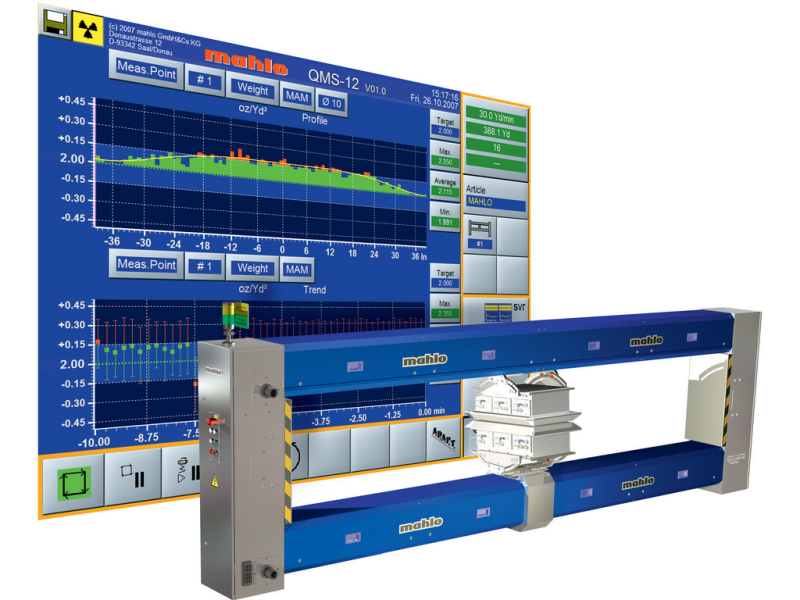

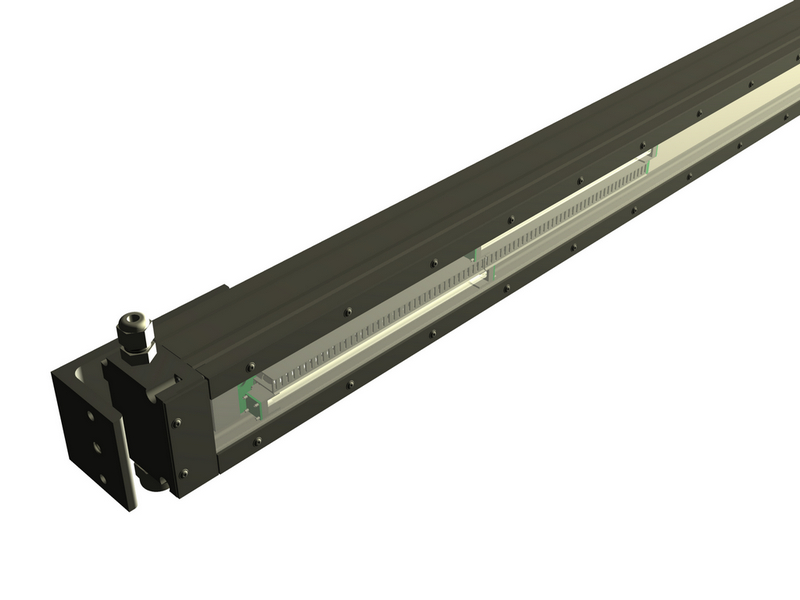

Qualiscan QMS-12 Bestseller

Traversing quality control system

Web process control

The Qualiscan QMS is a modular system for measuring, logging and controlling critical process parameters over the entire width of the product, including basis weight,…

Show details

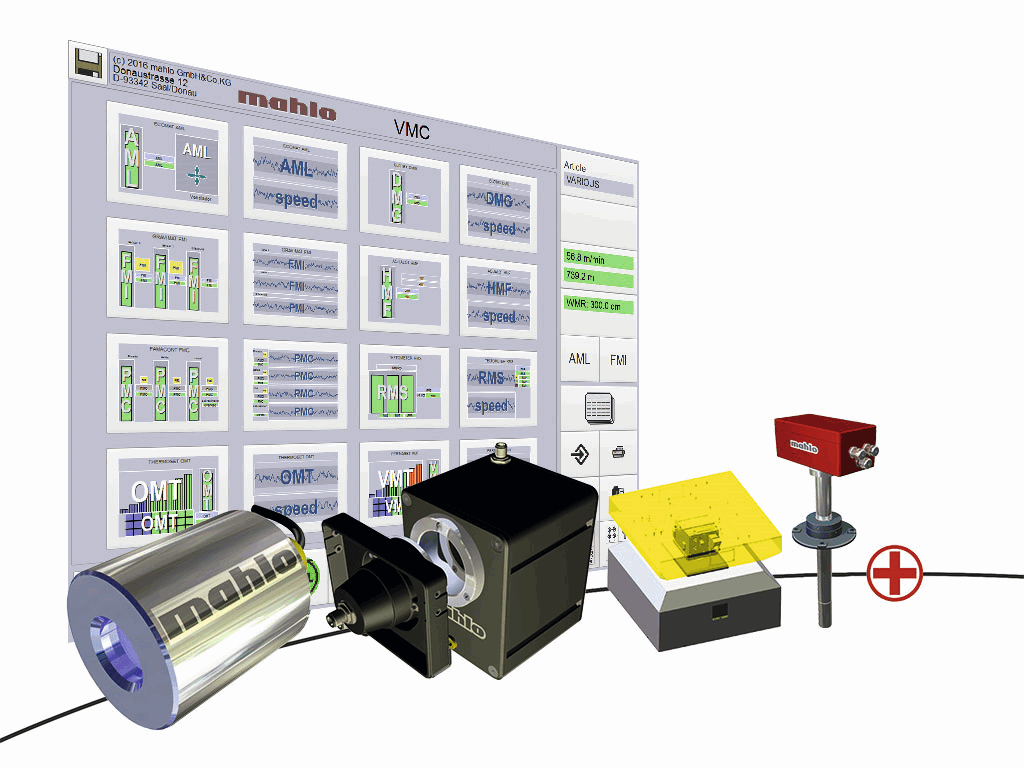

Optipac VMC-15

Modular process control system

Optimizes finishing

The Orthopac VMC is a modular process control system for textile refinement. It optimises drying or fixing processes as well as the processes all about the stenter. The…

Show details

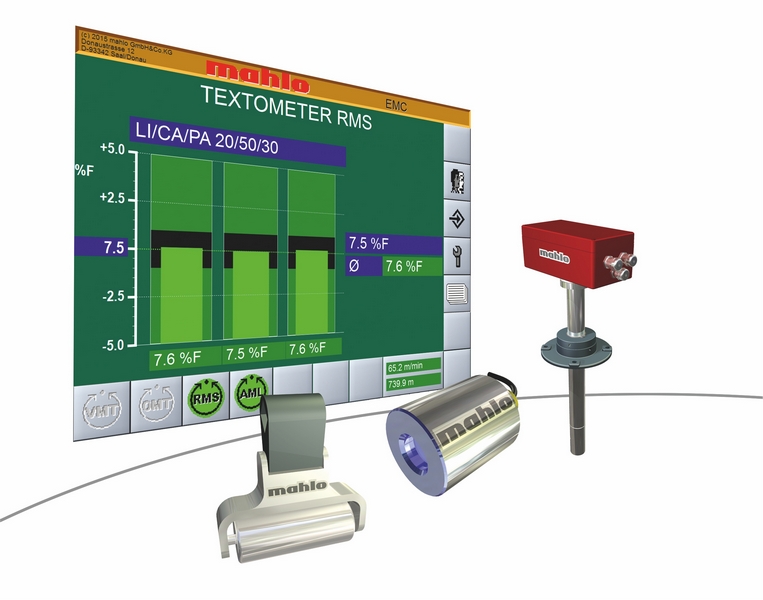

Ecopac EMC-15

Process control system for drying processes

Optimizes drying

The Ecopac EMC uses the state of the art microprocessor technology to ensure product quality and optimise the energy balance for drying processes. The modular system for…

Show details

Famacont PMC-15

Control of thread density / course density / basis weight

Optolectronic sensor / camera sensor

The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual…

Show details

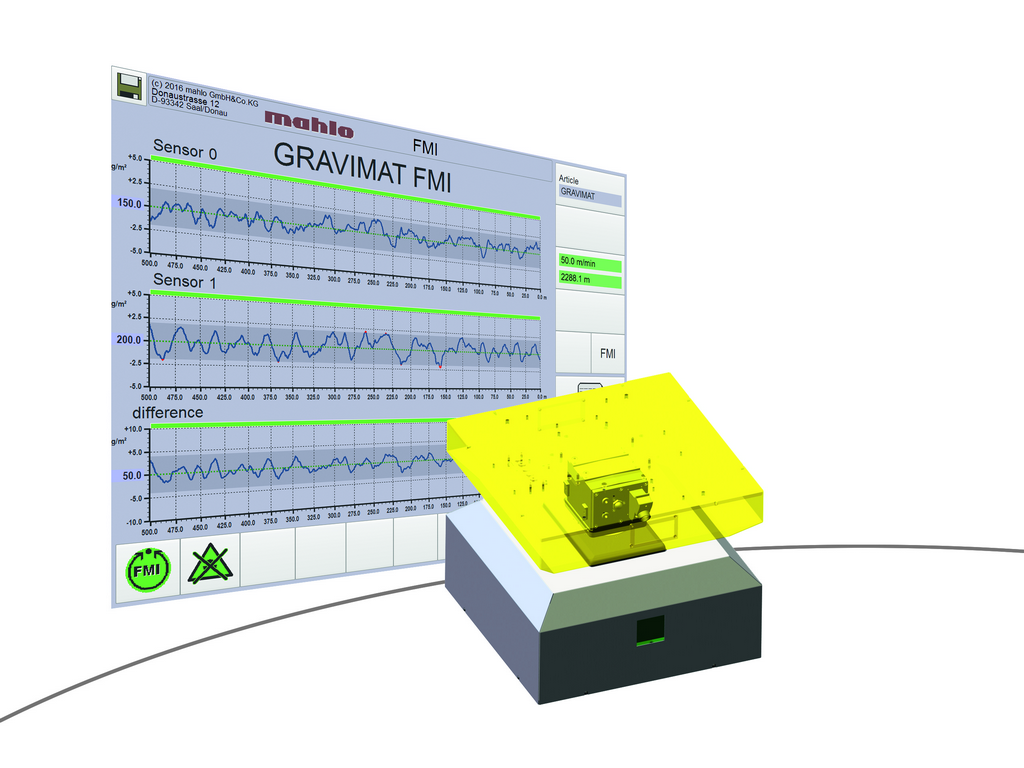

Gravimat FMI-15

Control of basis weight / thickness

Transmission of beta rays

The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The measurement is based on the…

Show details

Wilot WMR-12

Measurement of product width

Reflexion of infrared light

Automatic width measurement on a running product web. IR LEDs used in reflective mode continuously and precisely determine the product width. The sensor module only…

Show details

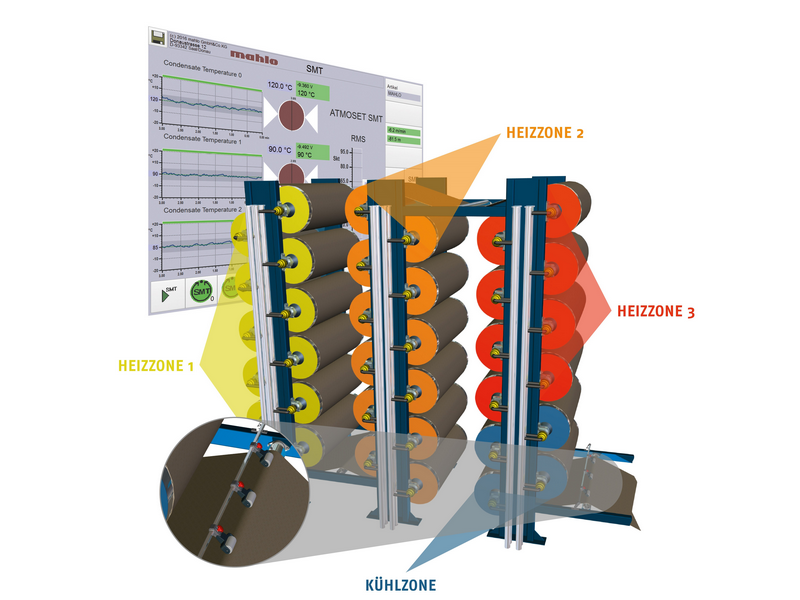

Atmoset SMT-15

Drum dryer control optimises heating performance

Condensate temperature control

The Atmoset SMT regulates the residual moisture of the tissue with steam-heated cylinder dryers. The deviation of the condensate temperature from a preset…

Show details

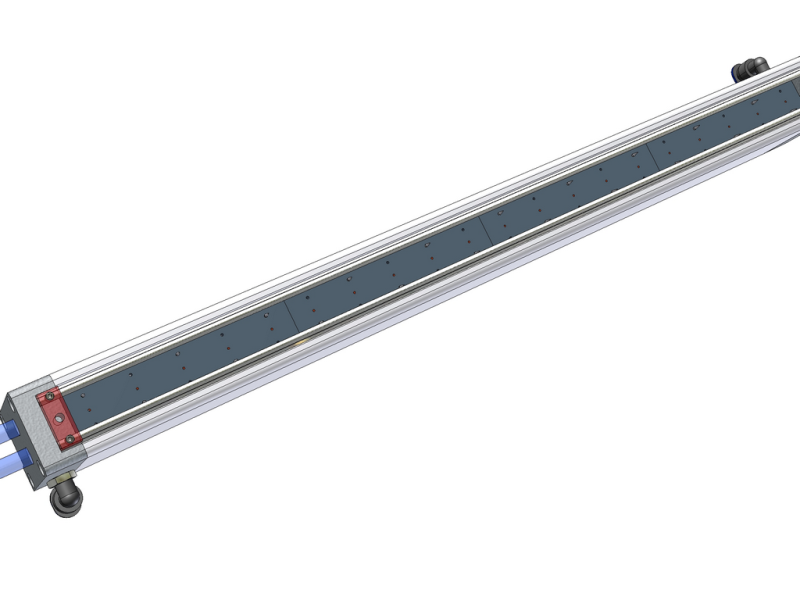

Antistat AMW-12

Discharge system for static charge

Ionisation of the air

The Antistat AMW ioniser for trouble-free processing of synthetic materials and of textiles with high charge separation. By ionising the ambient air, the electrostatic…

Show details

Ecosense ZS-12

Control of exhaust air humidity

Measurement of steam

Much unused energy is wasted through the exhaust air during drying processes without appropriate control. The Ecomat AML optimises the heating energy required by monitoring…

Show details

Thermosense HP270

Measurement of the fabric temperature

Infrared pyrometer

The Thermosense HP270 is used for non-contacting temperature measurement in driers and stenters and records the temperature of running product webs. The sensor is…

Show details

Products must meet certain specifications or remain within a narrow tolerance range to achieve a certain level of quality. To continuously achieve and maintain this level, automated process control checks critical parameters such as temperature, weight or humidity.

High-precision sensors can easily measure and control the smallest deviations, ensuring an uninterrupted production process with minimal material loss.

With reliable process control data, adjustments can be made to the manufacturing or finishing process as needed without effort. For seamless digital communication in the context of Industry 4.0, Mahlo offers a cross-system solution here with easy entry and effortless scaling.