Beta transmission is the most common principle for gauging basis weight, and suitable for almost every application. It is often used for coating & converting processes in textile finishing, nonwovens, film extrusion, sheet extrusion, calendering processes and on other coated materials. Precise measurements on moving webs are the result of using extremely efficient beta radiation detectors. Depending on the requirements, different isotopes are available for different applications.

Principle of beta transmission

Principle of beta transmission

The intensity of beta rays is weakened according to the mass of the penetrated layer. Some beta particles get through the material, some particles are stopped. This weakening allows gauging the basis weight of nearly all materials. Different isotopes (Krypton, Strontium, Promethium) are used for different weight ranges. In coating processes, several beta gauges can be used to record the application quantity as a difference in weight.

Except for very low weight ranges, beta transmission is the universal method for measuring basis weight. However, certain radiation protection requirements must be complied with due to the weak radioactive isotopes. The density of the product web can also be determined by beta gauges in combination with thickness sensors. However, is the density of the measured product known and remains constant, the material thickness can also be determined via the basis weight by the beta gauge alone.

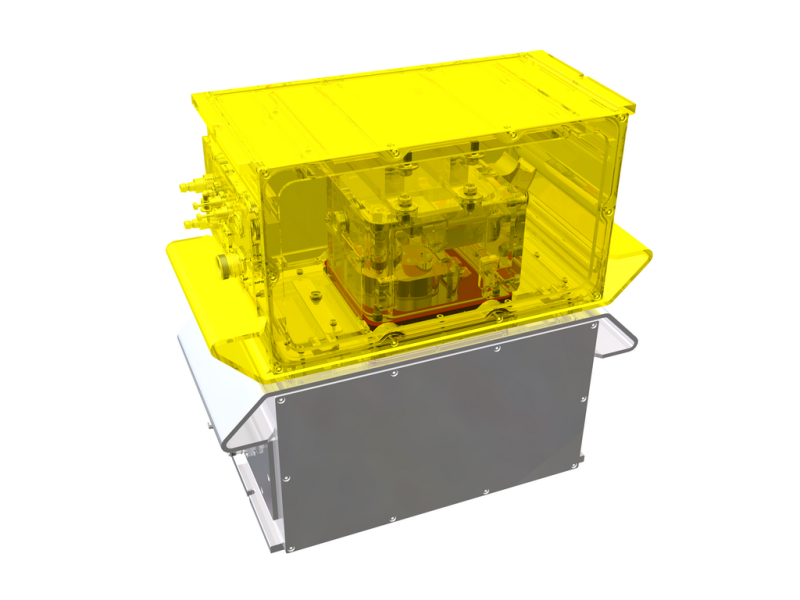

Gravimat FMI/DFI

Measurement of basis weight (mass per unit area) / thickness /density

Transmission of beta rays

The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The measurement is based on the…

Show details

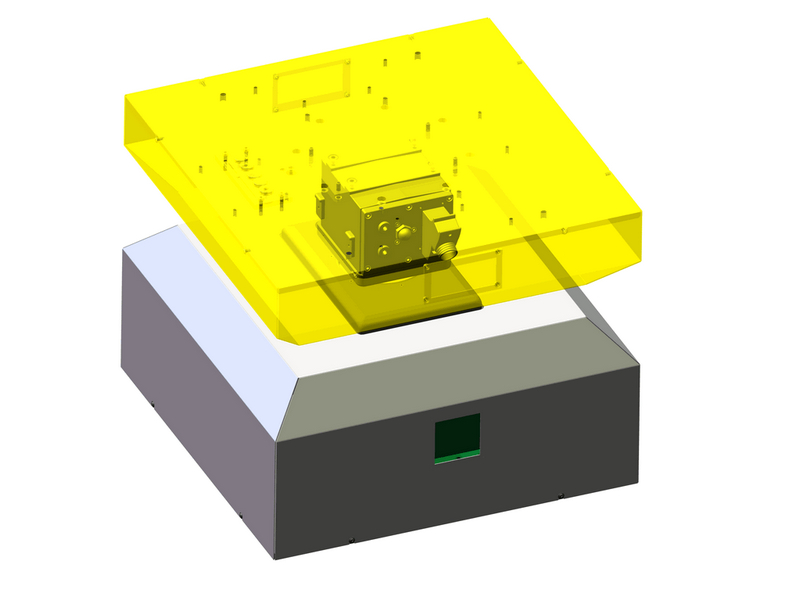

Gravimat FMI

Control of basis weight / thickness

Transmission of beta rays

The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The measurement is based on the…

Show details