Thickness measurement

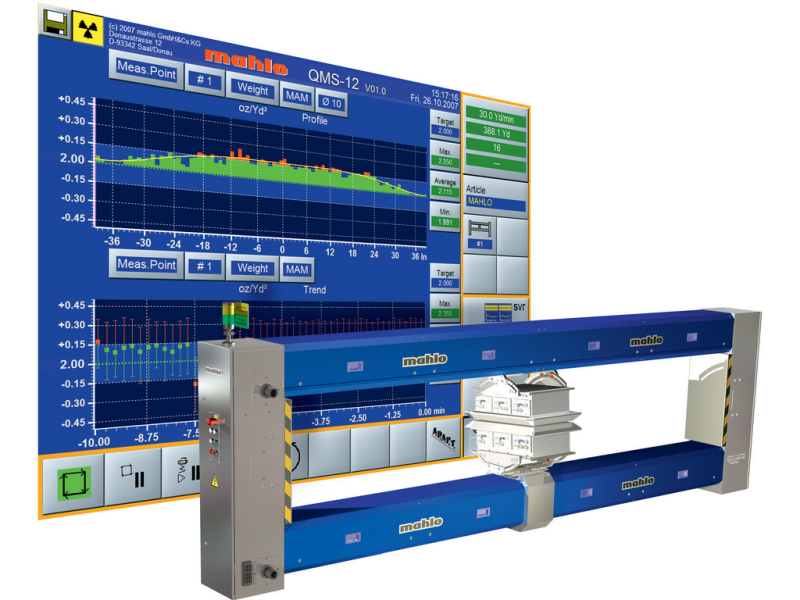

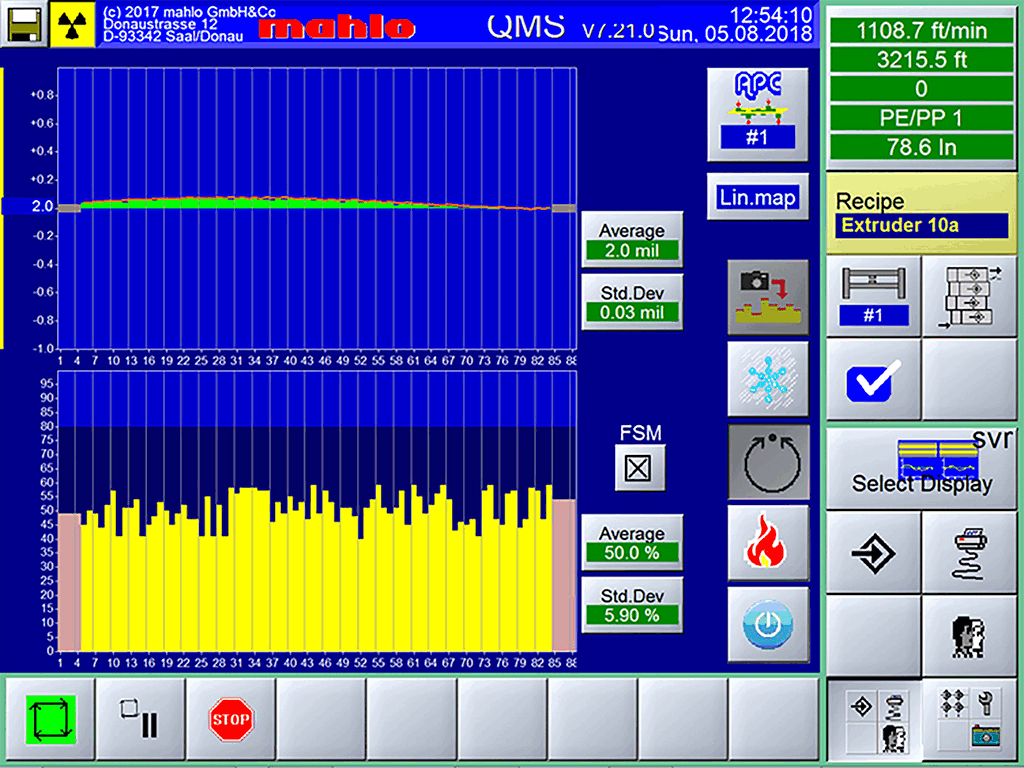

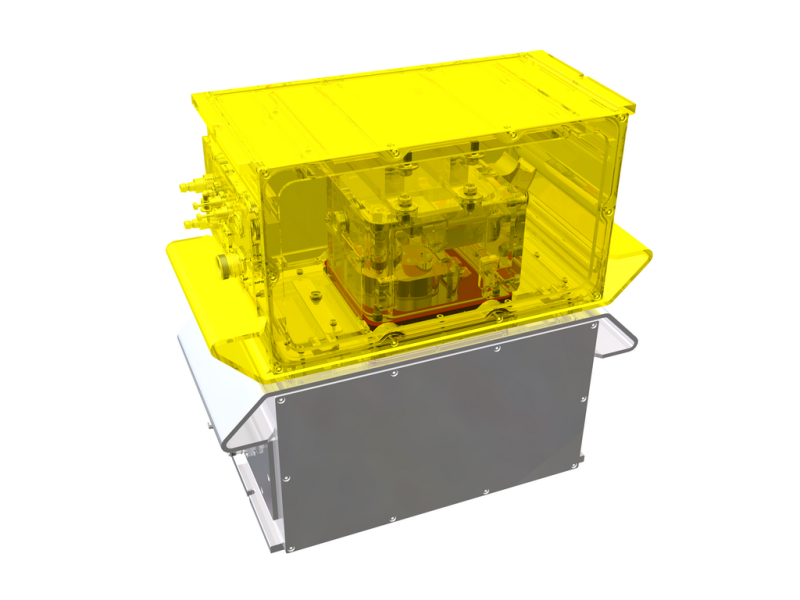

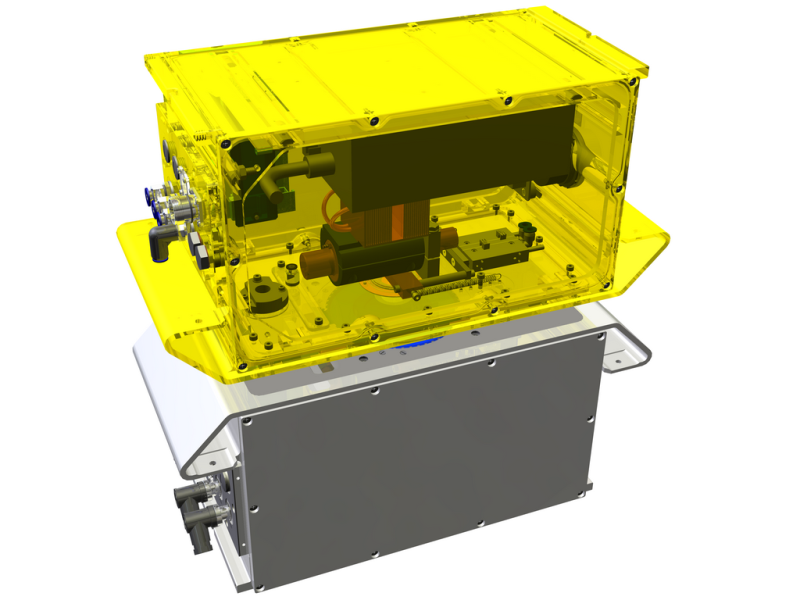

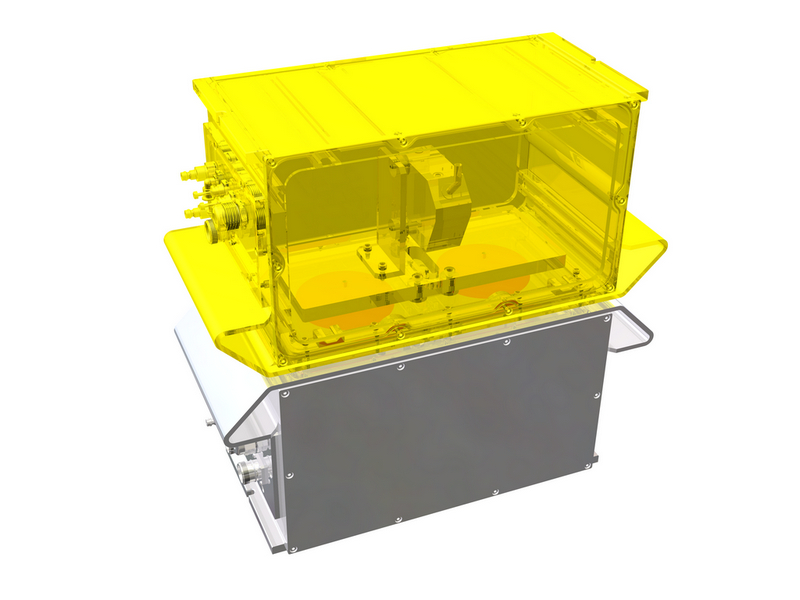

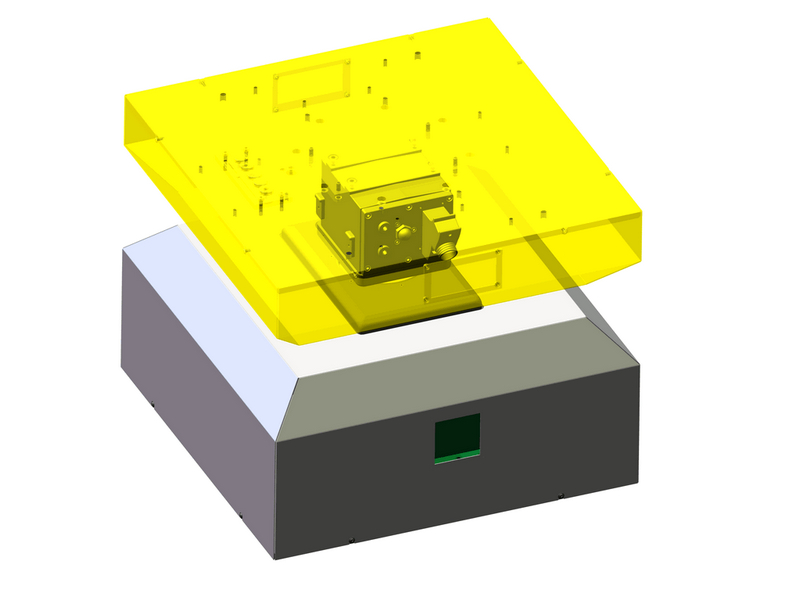

Non-contact measurement of thickness and layer thickness of continuous web processes

Versatile measuring methods individually adapted to your application

All measuring technologies used by Mahlo are non-contact and on-line, that means they can be used during the continuous production. The necessary method is selected individually for the requirements of the application. This guarantees optimum accuracy and measuring speed.

Mahlo offers a variety of thickness measurement methods for a wide field of applications and materials. They range from laser measurement, light band shadowing or interference measurement to infrared measurement and X-ray or isotope technology.

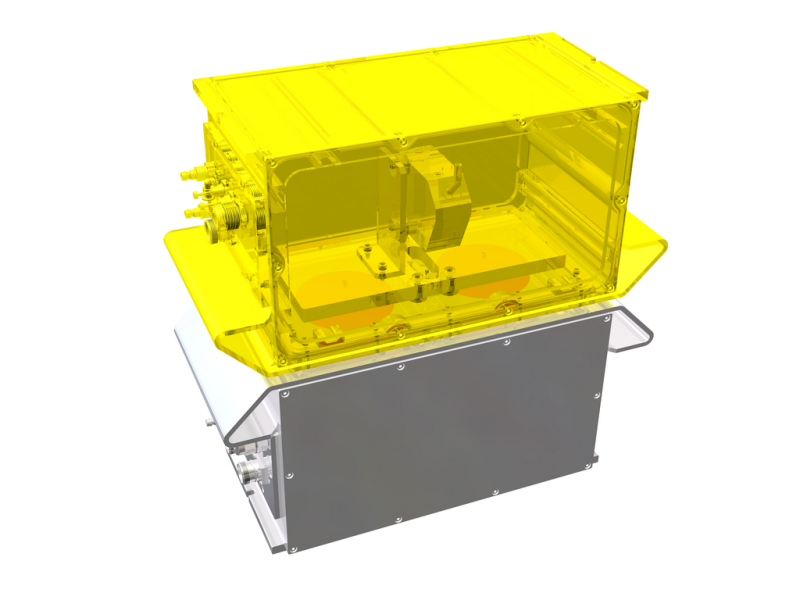

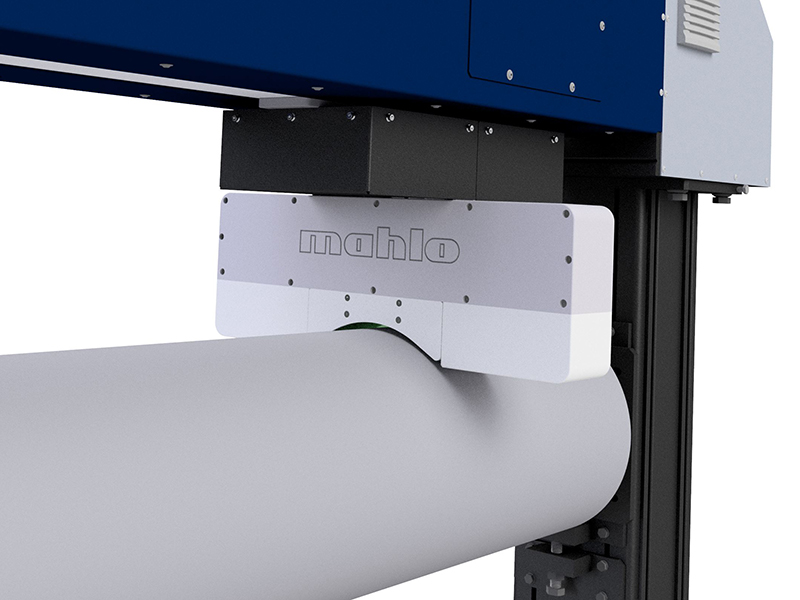

For single-sided thickness measurements, only one sensor is directed at the target. Thus, either a part of the target thickness (e.g. coating thickness) or the complete target thickness is detected.

Two-sided thickness measurements are carried out with one or more pairs of sensors. These are mounted in one axis to each other and measure synchronously to the target in the measuring gap. The difference between the individual measurement results gives the target thickness.