Mahlo is your partner in the fields of film & sheet extrusion as well as coating, converting and calendering. The extrusion market is highly competitive and requires expert knowledge and quality control systems that are both flexible and configurable.

With a strong and experienced partner like Mahlo at your side you get a quality control system that is both universally applicable and individually adaptable. This gives you the decisive competitive advantage in the ever-changing and complex market requirements for highest product quality.

Our expertise in on-line film & sheet extrusion measurement and control spans more than two decades. With our knowledge in the areas of plastics and films, extrusion, coating and calendering, we can adapt our measuring systems and process control individually for the following processes:

Products for Extrusion & Film

Find suitable products for your extrusion applications

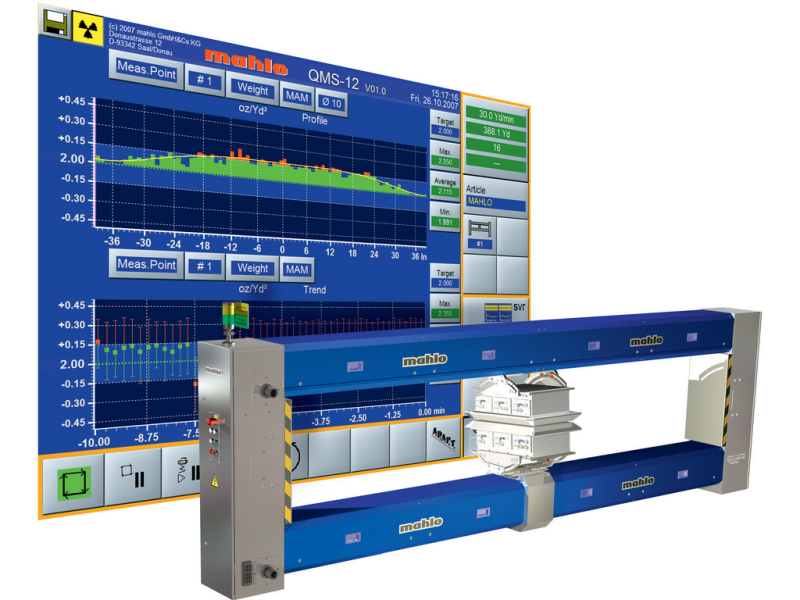

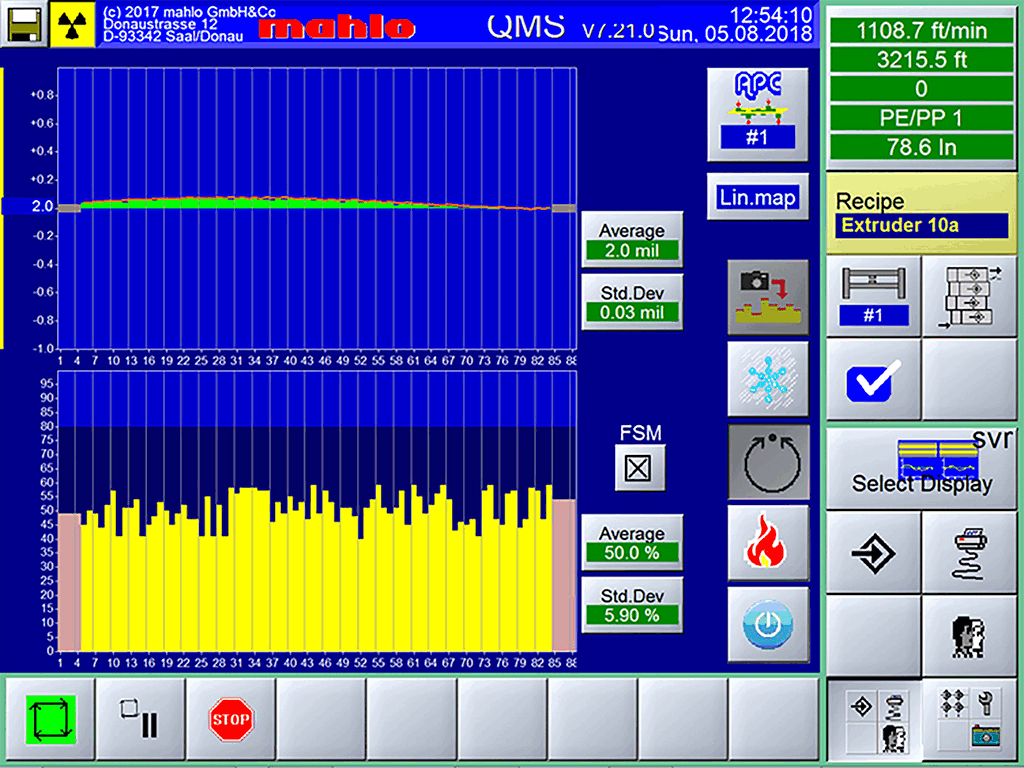

Qualiscan QMS-12 Bestseller

Traversing quality control system

Web process control

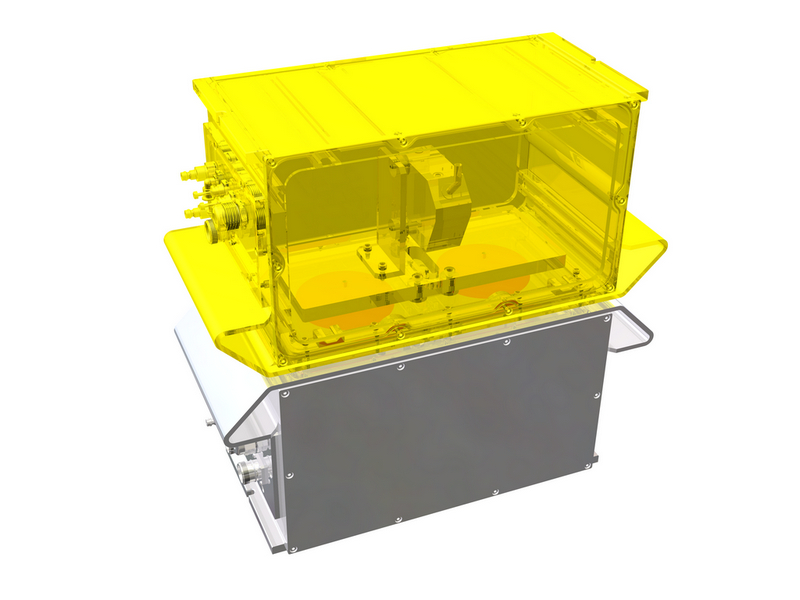

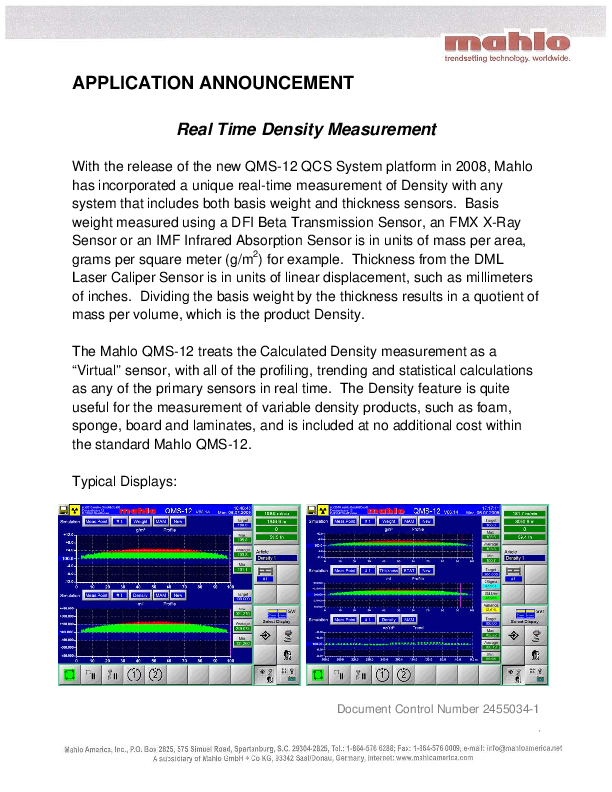

The Qualiscan QMS is a modular system for measuring, logging and controlling critical process parameters over the entire width of the product, including basis weight,…

Show details

Diecontrol APC Pro

Automatic Extrusion Die Control System

Automatic control of thermal diebolts of extrusion dies

The DieControl APC Pro automatically controls thermal bolts of extrusion dies according to the earlier measured cross-section profile of…

Show details

mLog enhanced

Data analysis and management

The mLog software is an application for data logging and interactive analysis of historical data for Mahlo equipment. The desktop application runs on an office PC and provides a comfortable…

Show details

Sensors

The right tool for every application

The Qualiscan QMS is a modular system consisting of multiple measuring sensors and measurement frames acting as intelligent nodes on a network. Some frames can run up to five Mahlo sensors at once, continuously, precisely and rapidly across the online product.

The versatile sensors and measuring devices of the Qualiscan QMS series can sense, log and continuously control such parameters as weight per unit area (basis weight), coating weight, thickness and moisture in a variety of web-type products.

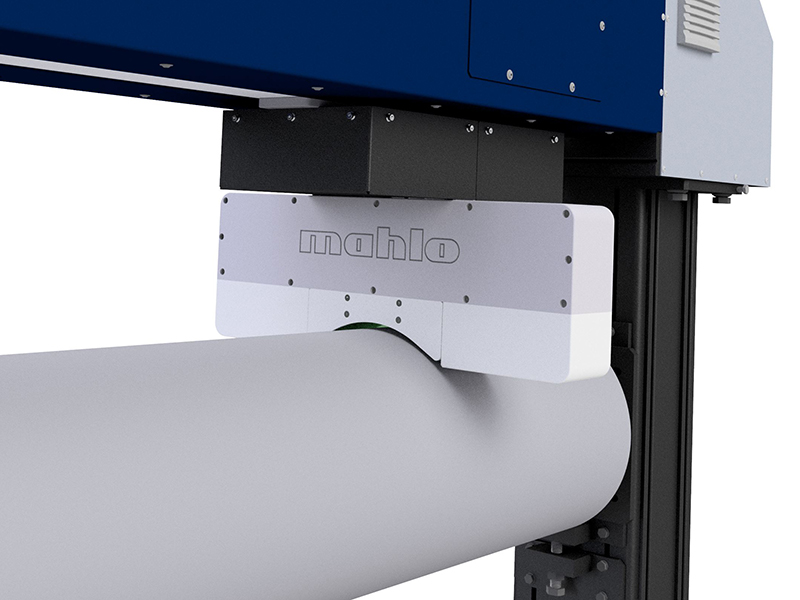

Calipro DML

Measurement of thickness (contactless)

Laser triangulation

The Calipro DML optical system uses laser triangulation online to measure the thickness or coating thickness of various materials with the highest accuracy.

Show details

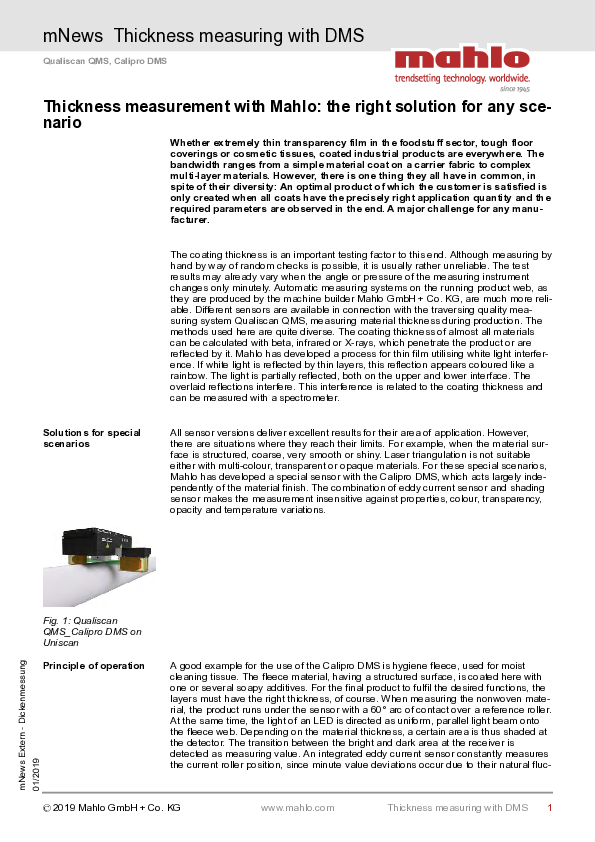

Calipro DMS

Measurement of thickness (contactless)

LED micrometer

Calipro DMS measures the material thickness of the product using a light curtain. It is insensitive to colour, transparency and opacity as well as largely independent of the…

Show details

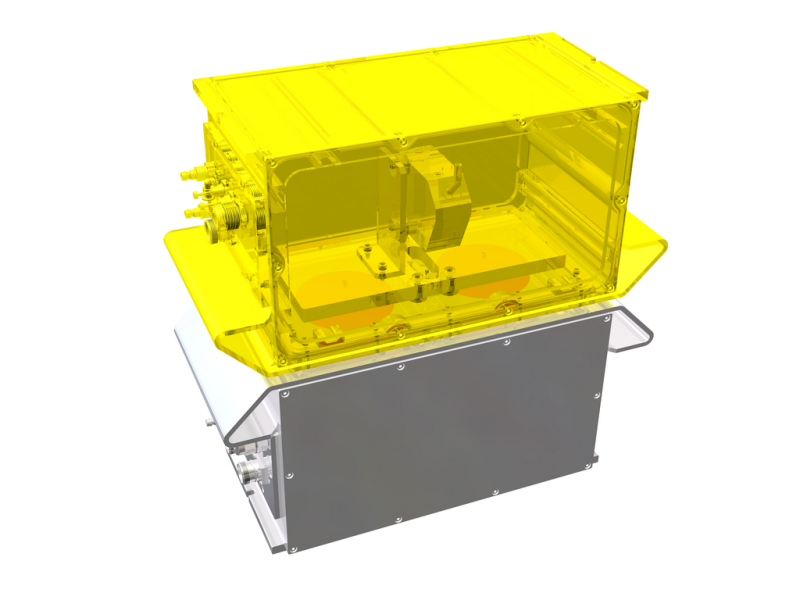

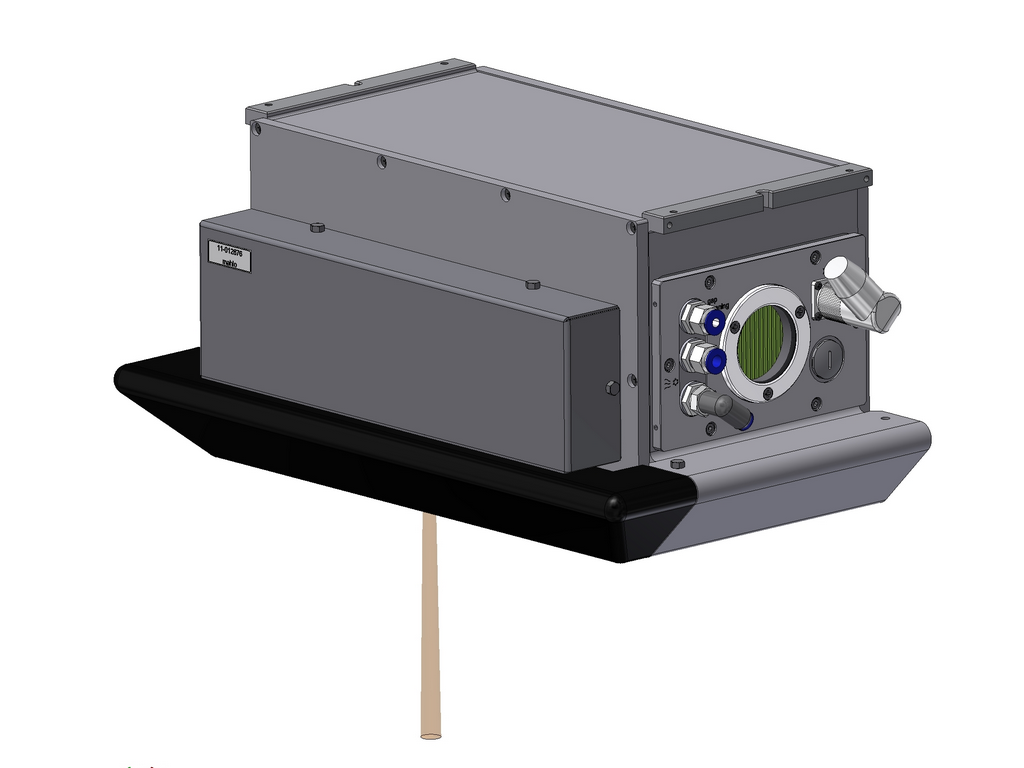

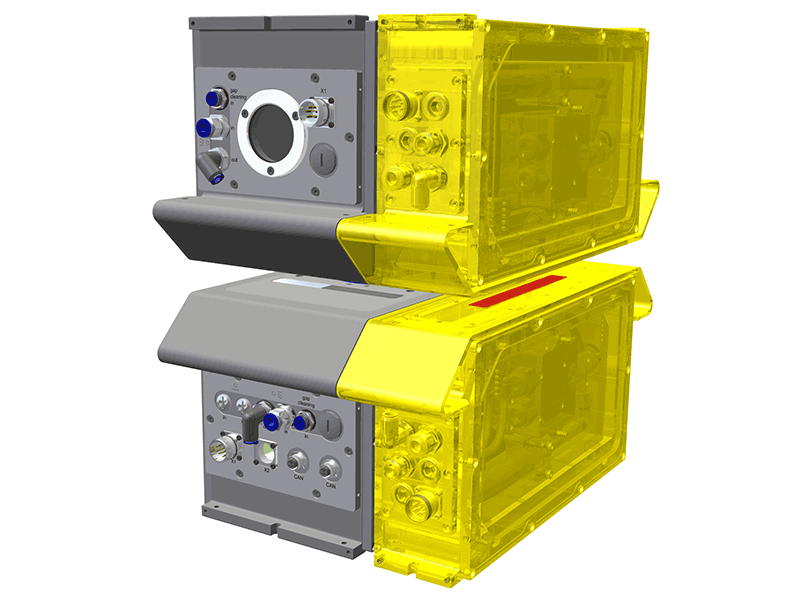

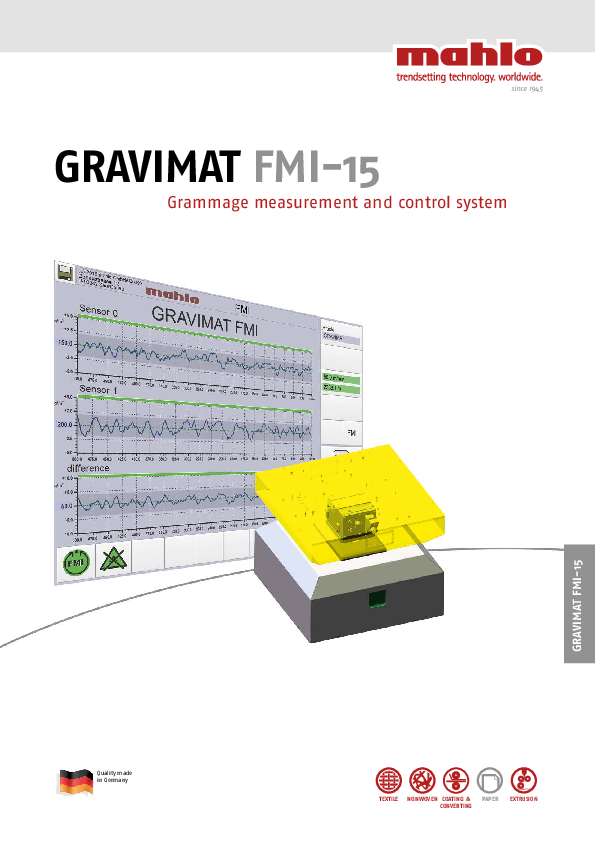

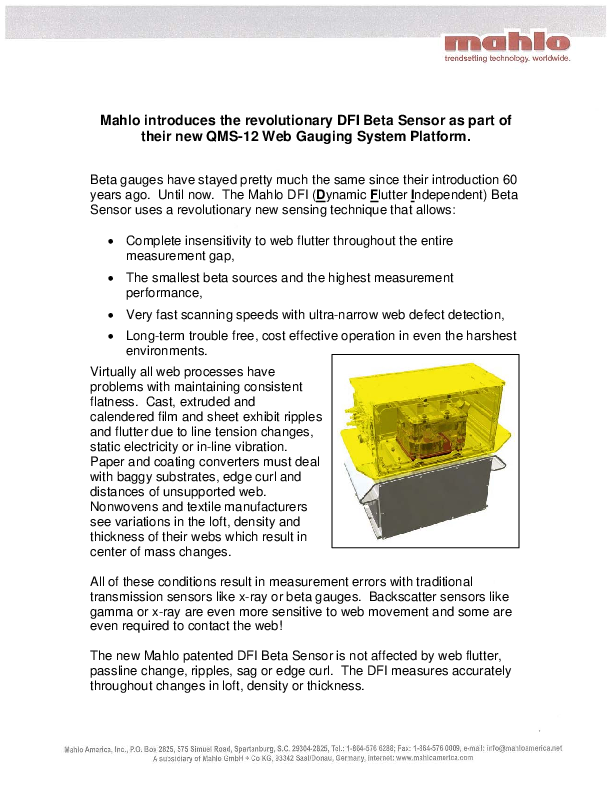

Gravimat FMI/DFI

Measurement of basis weight (mass per unit area) / thickness /density

Transmission of beta rays

The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The measurement is based on the…

Show details

Gravimat FMX

Measurement of basis weight (mass per unit area) / thickness

Backscattering of X-rays

The weight monitoring and control system measures the weight continuously, without contact, destruction-free and on moving product. The X-ray radiation from an X-ray…

Show details

Gravimat FMX-T

Measurement of basis weight (mass per unit area) / thickness / density

Transmission of X-rays

The Gravimat FMX-T permits the contactless and traversing measurement of basis weight (grammage) / thickness of the running product webs over the entire product width.…

Show details

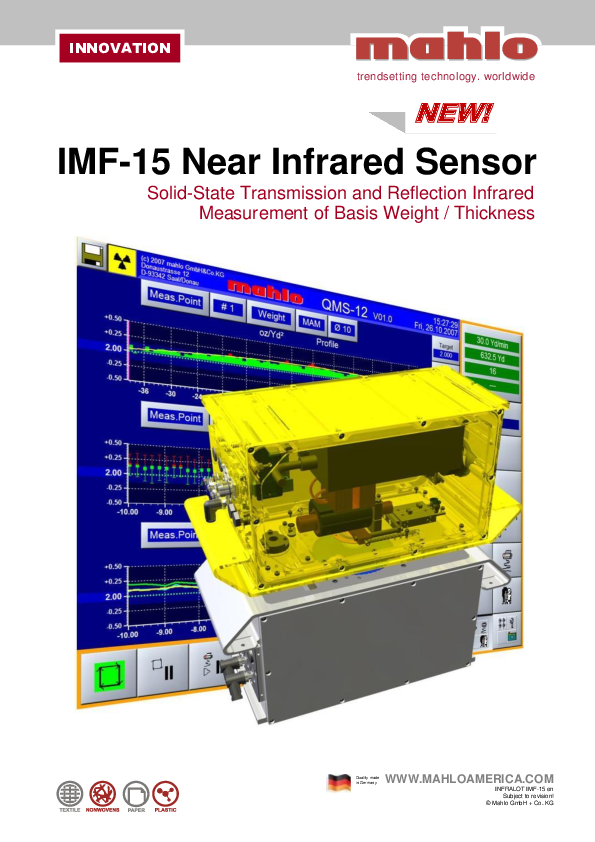

Infralot IMF

Measurement of moisture / organic compound

Absorption/reflexion of infrared light

Infralot IMF uses optical evaluation of the absorbed/reflected light energy in the near-infrared range to continuously measure and control material…

Show details

Infrascope NIR

Measurement of basis weight (mass per unit area) / moisture

Absorption of infrared light

The Infrascope NIR monitors the absorption of infrared energy of all components on or in the web in the near infrared range. Measuring over the entire spectrum…

Show details

Optoscope WLI

Measurement of thickness / layer thickness

White light interference

White light from the upper and lower boundary surfaces of thin films is reflected differently. Interference measurement allows for the precise measuring of transparent…

Show details

Webtemp WTP

Measurement of web temperature

Infrared measurement

Infrared sensor for the surface temperature in the measuring gap of the quality control system Qualiscan QMS. For some applications an even temperature distribution in the…

Show details

Wilot WMR

Measurement of product width

Reflexion of infrared light

Automatic width measurement on a running product web. IR LEDs used in reflective mode continuously and precisely determine the product width. The sensor module only…

Show details

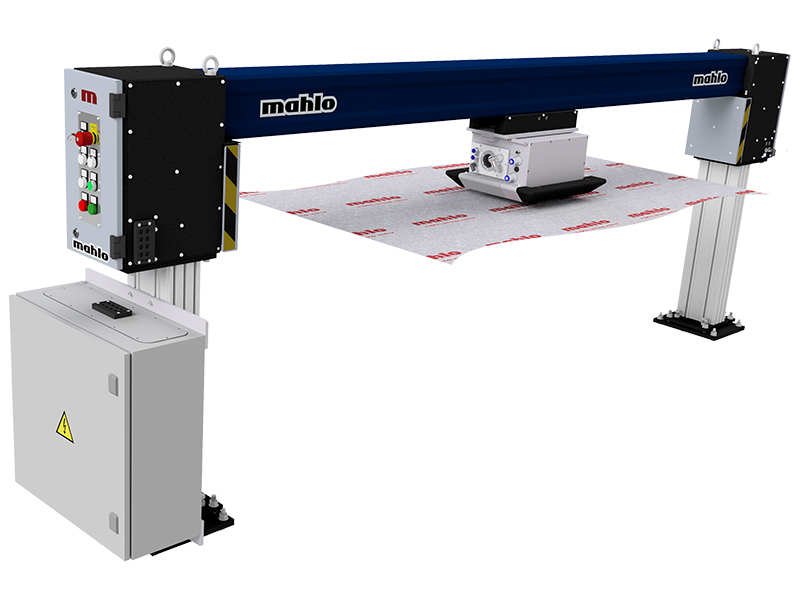

Scanners

Universal application

The measuring frame traverses the sensors on-line across the whole product width and provides a cross-machine direction profile of basis weight, thickness or moisture on the display console that is a crosssection of the manufactured product.

One or more different measuring frames can be connected to a Qualiscan QMS system. Connection is made via a normal network cable, a standard 230/115 V source supplies the power.

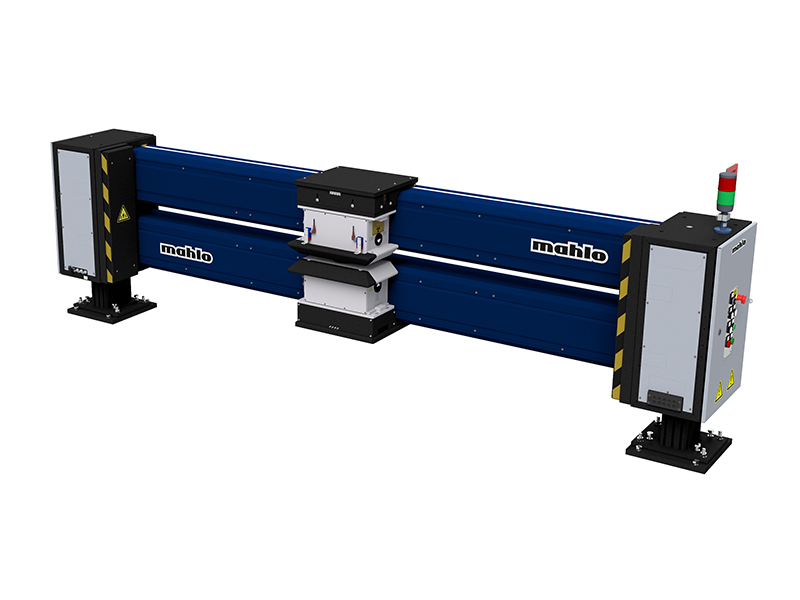

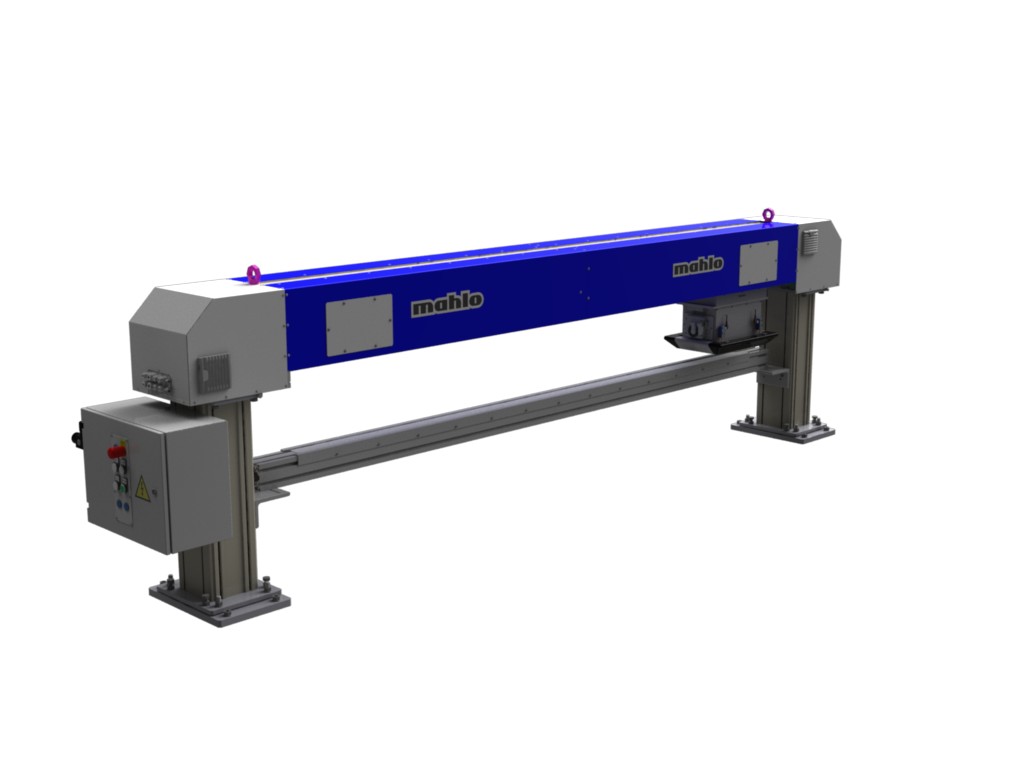

Webpro L-II

Double-sided measuring frame for large widths

Big O-frame, many sensors

The WebPro L traversing frames represent the pinnacle of the Mahlo scanning frame family. They are available in traverse widths of up to 6,6 meters, and can run up to…

Show details

Webpro M

Double-sided measuring frame for normal widths

Medium O-frame

WebPro M traversing scanners are found on a wide variety of web processing applications in an assortment of industries, and are legendary for their robust construction and…

Show details

Webpro MH

Double-sided measuring frame for normal widths and thick products

Medium O-frame

WebPro M traversing scanners are found on a wide variety of web processing applications in an assortment of industries, and are legendary for their robust construction and…

Show details

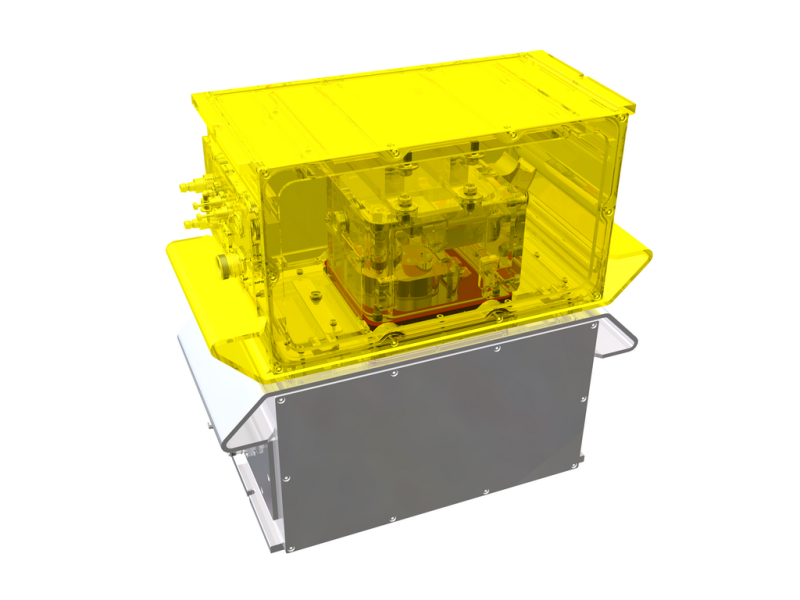

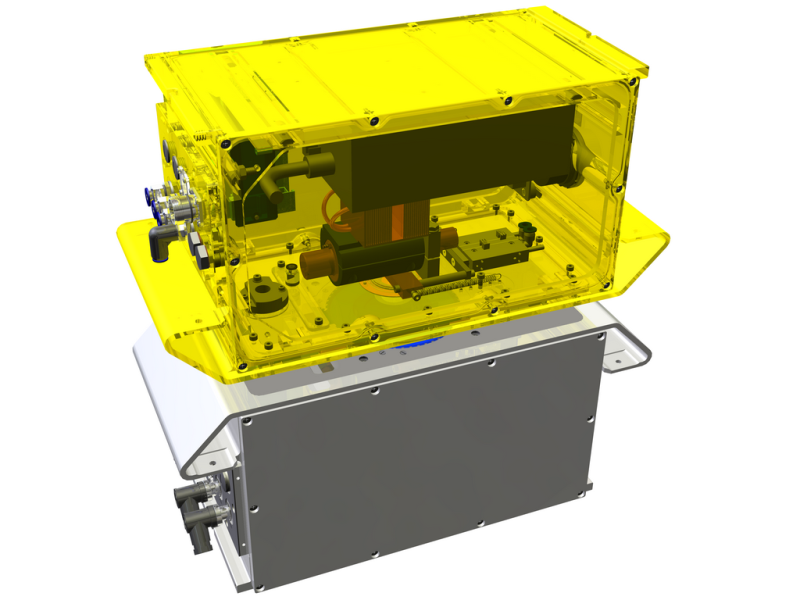

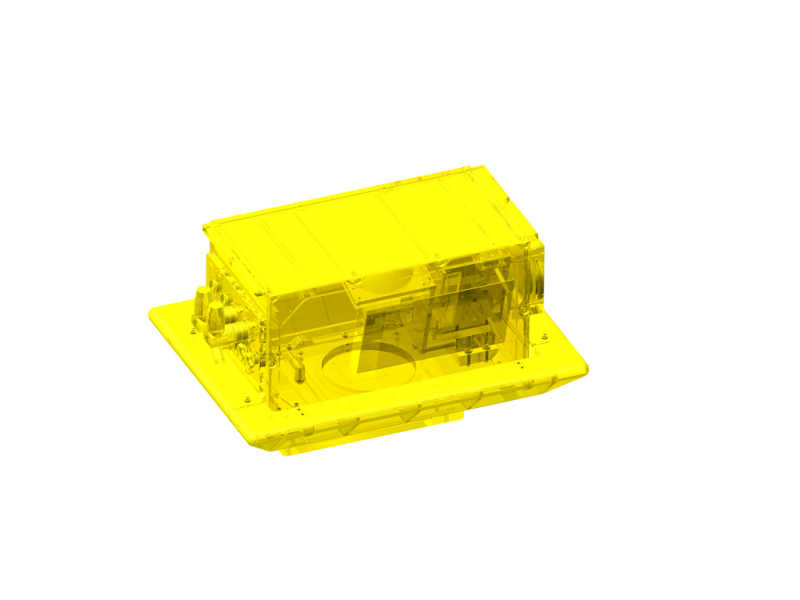

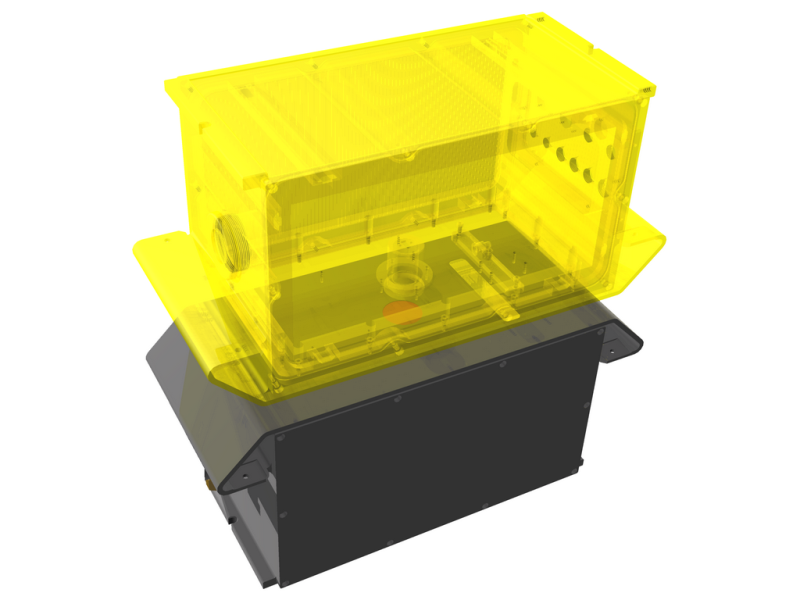

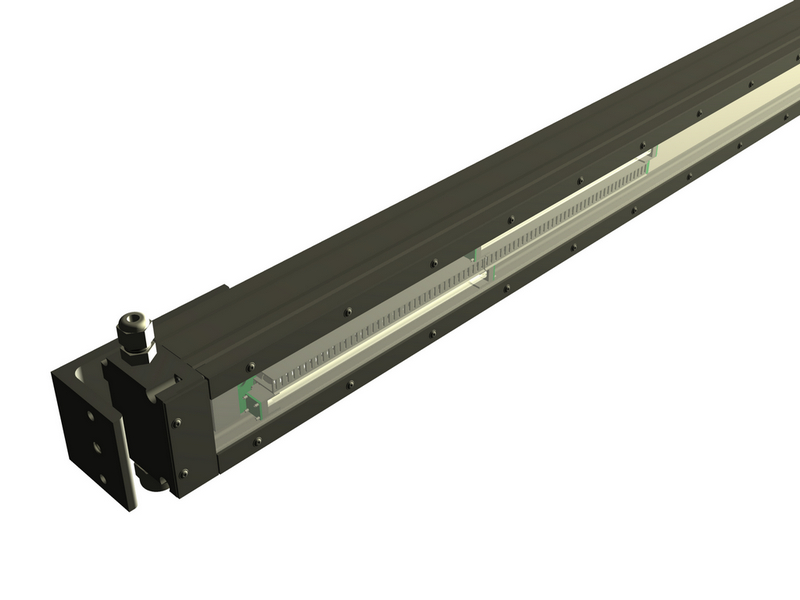

Webpro S-II

Double-sided measuring frame for confined installation spaces

Extremely compact O-frame

The WebPro S traversing frames have been designed specifically to provide an exceedingly compact but rugged and reliable traversing platform for situations where…

Show details

Webpro XS-II

Double sided measuring frame for narrow webs

Compact O-frame for small widths

The traversing frames of the type WebPro XS are used for many applications in various industries and are distinguished especially by their rugged, reliable and…

Show details

Webpro XSH-II

Double sided measuring frame for narrow webs and thick products

Compact O-frame for small widths

The traversing frames of the type WebPro XS are used for many applications in various industries and are distinguished especially by their rugged, reliable and…

Show details

Uniscan M

Single sided scanner for large widths

Single sided measurement of wide webs

The UniScan traversing scanners are the single-sided counterpart to the double-sided O-frames of the WebPro series. They are specially designed to…

Show details

Uniscan S

Single sided scanner for normal widths

Single sided measurement of normally wide webs

The UniScan traversing scanners are the single-sided counterpart to the double-sided O-frames of the WebPro series. They are specially designed…

Show details

Uniscan XS-II

Single sided measuring frame for narrow webs

Single-sided scanner for small widths

The UniScan traversing scanners are the single-sided counterpart to the double-sided O-frames of the WebPro series. They are specially designed to…

Show details

Profix

For fixed measuring points

Fixed measuring point

A fixed measuring point is used in simple applications where no cross-section of the entire web has to be measured.

As standard, the mounting frame consists of aluminum…

Show details

Accessories

Little helpers

Accessories and add-on devices for improving accuracy, quality and performance

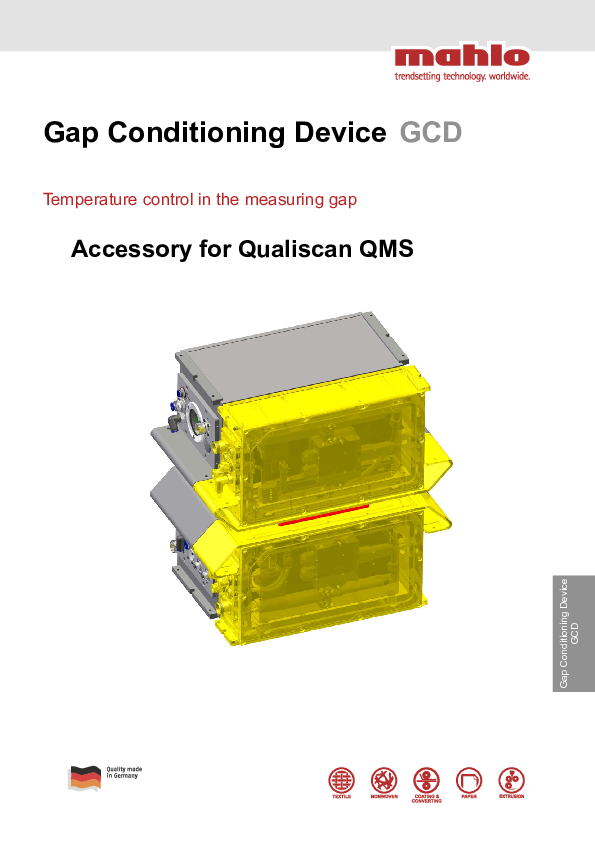

Gap Conditioning Device

Temperature control in the measuring gap

Measuring gap heating

The Gap Conditioning Device facilitates consistent temperature conditions for increased measuring accuracy.

Show details

Quality control

On-line Measurement and Control for continuous web processes

Process control

Measurement and control technology

Data Management

Software for logging and data analysis

Web inspection

Product web inspection systems

Success Stories

Success stories: How customers achieve their goals with Mahlo

Application Reports

Solutions for specific tasks

News

New information on Mahlo technology, products and service

Info

In-depth information on various products

Press

Mahlo in the media

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

In extrusion, solid to viscous materials - usually plastics - are melted and extruded under pressure through a shaping opening. The process is used for a variety of materials. Most frequently certainly in plastics processing, but also for composite materials such as fiber-reinforced plastics, WPC (Wood-Plastic-Composites) or thermoplastic polymers such as PVC, PP, PE, PET and PA.

Substrates thicker than 1mm are commonly referred to as “sheets” while as for materials with less than 1mm thickness the term “film” is used.

Extrusion coating is the process of applying an additional layer on top of a substrate like plastic, foil or paper. The hot, molten layer material is usually pressed through a slot die onto a moving film or sheet. Layer thickness can be determined depending on the speed of the web and the slot gap.

Extruded products or extrusion coated products are used in the building industry, in the medical sector, as packaging, wrapping, lining, and much more.

From measuring basic parameters to controlling basis weight, thickness and coating weight simultaneously on wide, high-speed film lines, Mahlo provides the ideal solution to your film & sheet extrusion needs.

Utilizing advanced intelligent sensor and scanner techniques like beta gauges, X-ray sensors or infrared, microwave, laser or white light sensors, the measurements of the process are continuously checked with high precision.

Systems from fixed measuring points to traversing measuring systems for single and double-sided measurement with several synchronized scanners are available.