Principle laser line sensor

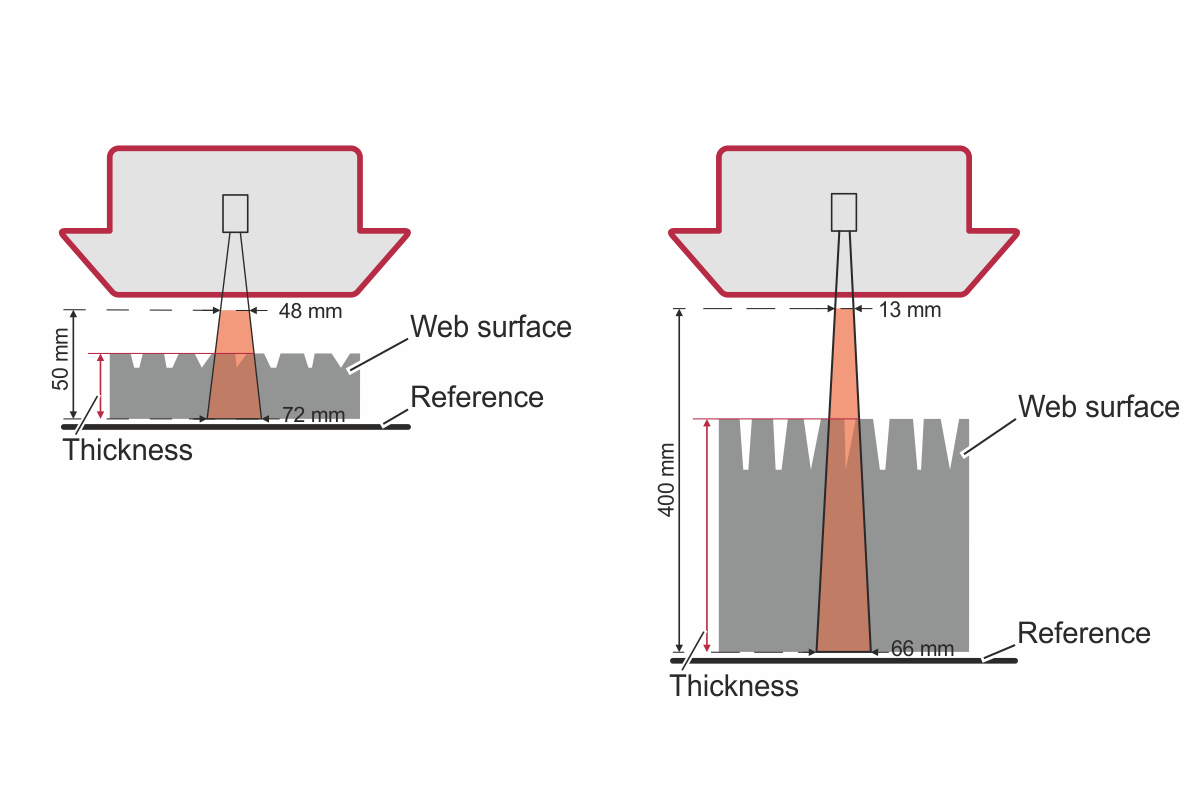

Distance measurement through angle calculation A laser beam is projected onto a measuring object and reflected from there. Depending on the distance, the reflected laser beam hits a CCD receiver at a certain angle. The distance to the measuring object is calculated by the position of the light dot on the receiver as well as the distance of the laser to the receiver. The material thickness can be determined this way.

With the single-sided measuring process, measuring is done against a roller or product guide. Error in the runout of the roller can be compensated by eddy current sensors. The single-sided variant is very suitable for flexible products and for products structured on one side. The unstructured side is measured then.

With the double-sided measuring process the top and back side of the product is scanned and the thickness is thus determined. This method achieves good results with rigid, inflexible products and nonwovens.

Calipro DML

Measurement of thickness (contactless)

Laser triangulation

The Calipro DML optical system uses laser triangulation online to measure the thickness or coating thickness of various materials with the highest accuracy.

Show details