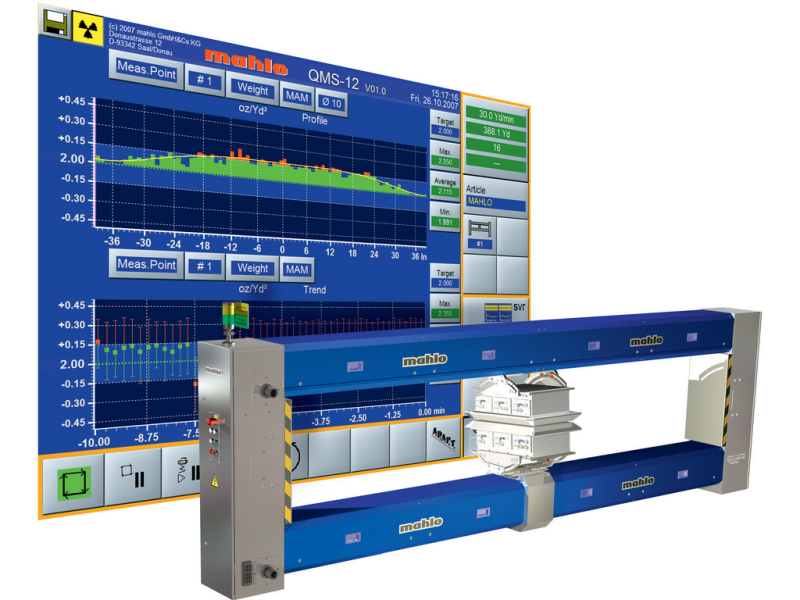

The Qualiscan QMS is the base for reliable on-line measurement and control. The modular web gauging system determines, logs and controls critical process parameters over the entire working width of running web. And since different tasks require different solutions, Mahlo offers a wide range of scanners and sensors for virtually any application and products in the extrusion, coating & converting, nonwovens, textile and paper industries. It's an easy and reliable way to control thickness, basis weight or density.

Scanners

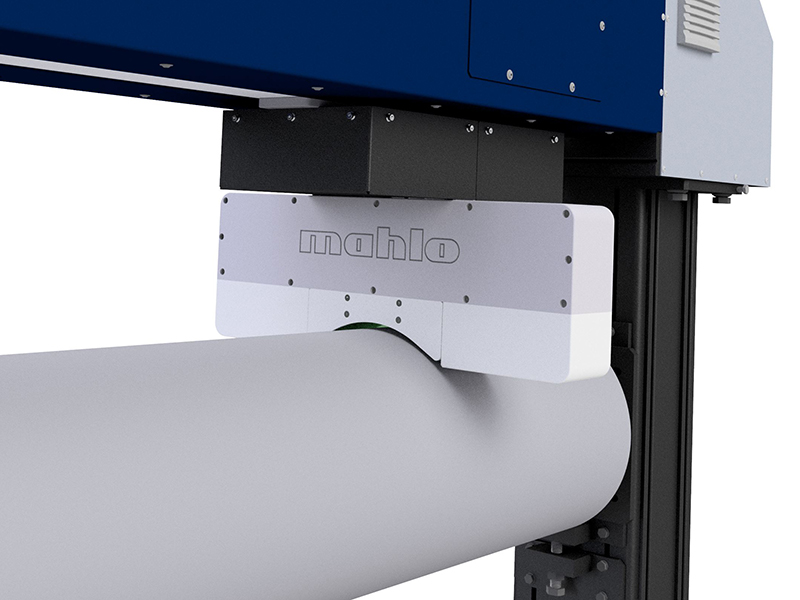

The environment in the production lines are as varied as the products and applications. Mahlo therefore has a wide range of measuring frames, from O-frames to single-sided and C-frames in various widths. The largest models can accommodate up to five sensors. With this web gauging equipment, the best conditions are created for optimum measurement results.

Sensors

The sensor portfolio includes all common measuring methods - of course always at the cutting edge of Mahlo technology. Following parameter can be measured or controlled:

- Basis weight

- Thickness / Layer Thickness

- Density

- Moisture

- Air permeability

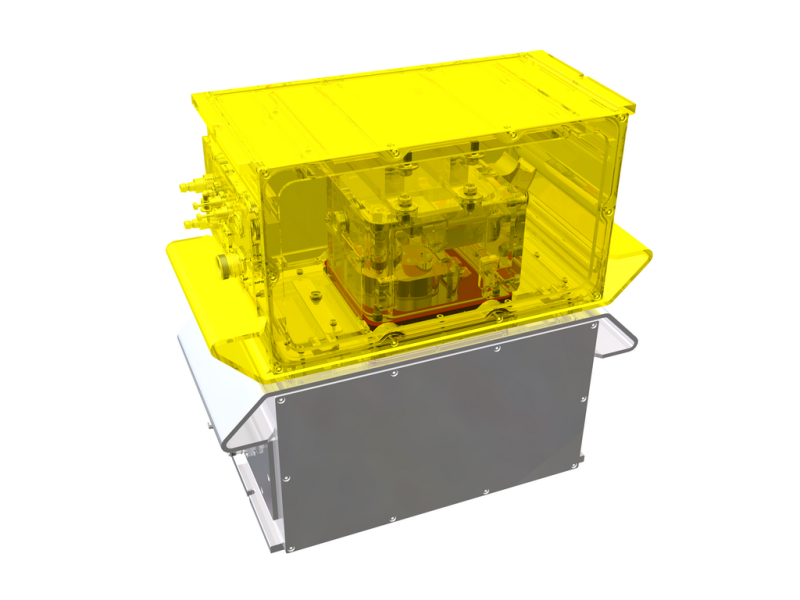

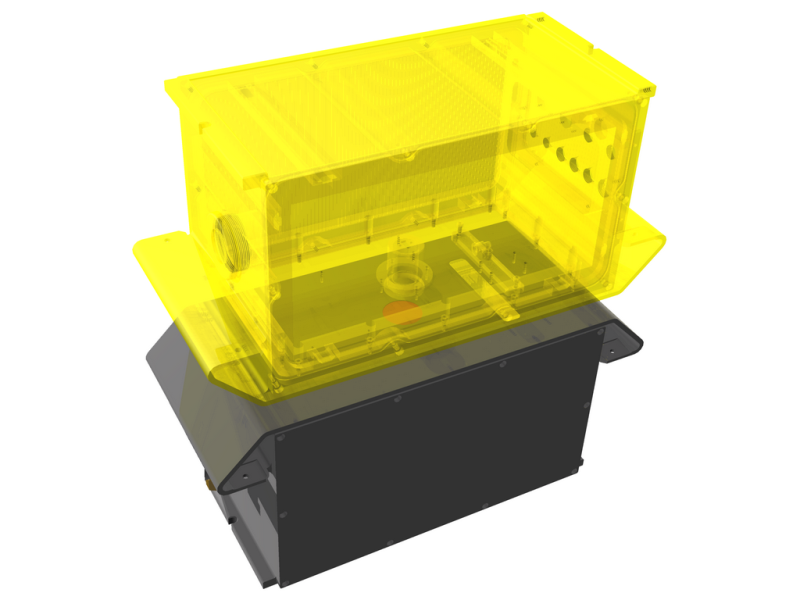

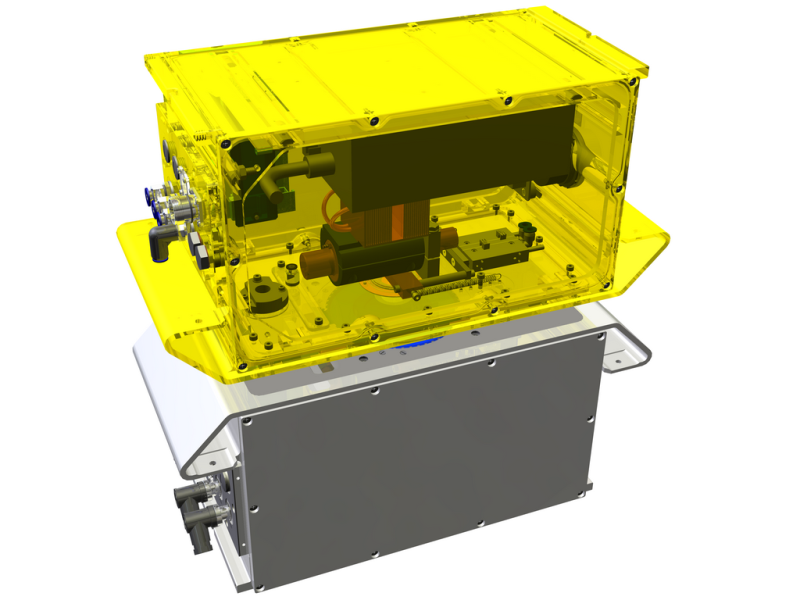

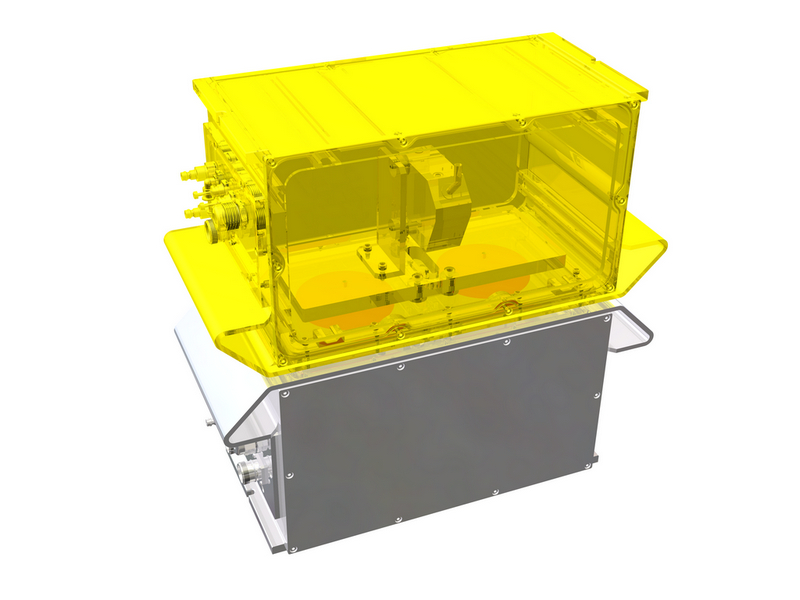

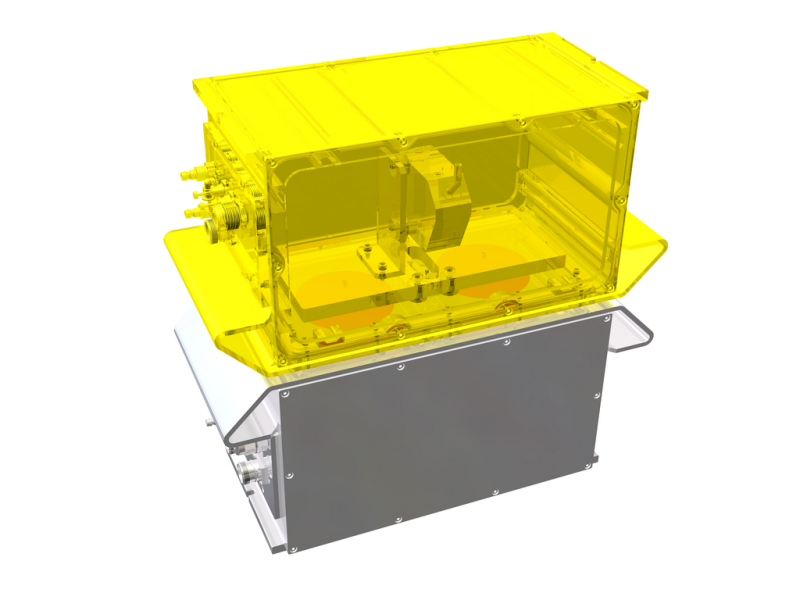

Beta gauges are the most renowned method for measuring parameters such as basis weight, thickness, and density. For different requirements of the web, different nuclides are available. However, certain radiation protection requirements must be complied with due to the weak radioactive isotopes.

IR sensors are especially suitable for gauging residual moisture, basis weight, and organic compounds. They can be used for all materials that exhibit an absorption spectrum in the infrared range. Measuring the weakened radiation of the web’s different spectral ranges, the moisture content and basis weight of different materials can be determined.

A very reliable method for determining thickness, density and basis weight is measurement with X-rays. The X-rays are directed at the fabric and penetrate it for the most part. A small part is backscattered. The basis weight can be calculated from this. In the case of X-ray transmission, the intensity of the radiation is weakened depending on the mass of the irradiated layer. The basis weight of almost all materials can be determined by the attenuation.

If clear or slightly opaque thin coatings are irradiated with white light, the light is partially reflected at both the upper and lower boundary surfaces. This results in interference colours. The frequencies of this interference are a measure of the layer thickness and are determined by an FFT algorithm.

In thickness measurement with laser triangulation, a laser beam is projected onto the web and reflected from there. Depending on the distance, the reflected laser beam strikes a CCD receiver at a certain angle. The distance to the object to be measured is calculated by the position of the light spot on the receiver and the distance from the laser to the receiver.

For special cases such as structured, rough, very smooth or glossy material surfaces Mahlo has a sensor in its web gauging equipment that operates largely independently of the material surface. A combination of eddy current and shading sensor makes the measurement insensitive to texture, colour, transparency, opacity and temperature fluctuations.

Air permeability is not only important for the exchange of air and wearing comfort in textiles, but also plays a decisive role in the functionality of filters, films, paper or composite materials. To determine the air permeability, Mahlo measures the pressure drop across the running fabric web. The measuring system draws air through the material at a certain pressure. The measurement of the resulting air flow defines the air permeability of the material.