Flat bed printing & Rotary printing

Stamperia Pezzoli offers printing and finishing services for textiles for more than 35 years, maintaining the highest quality standards in every step of the manufacturing process and ensuring a highly competitive service in terms of technology and styling. Stamperia Pezzoli's finished textiles are used worldwide mainly for furniture and linen in households, hotels and hospitals. They are also used in the shipping industry and in the outdoor sector.

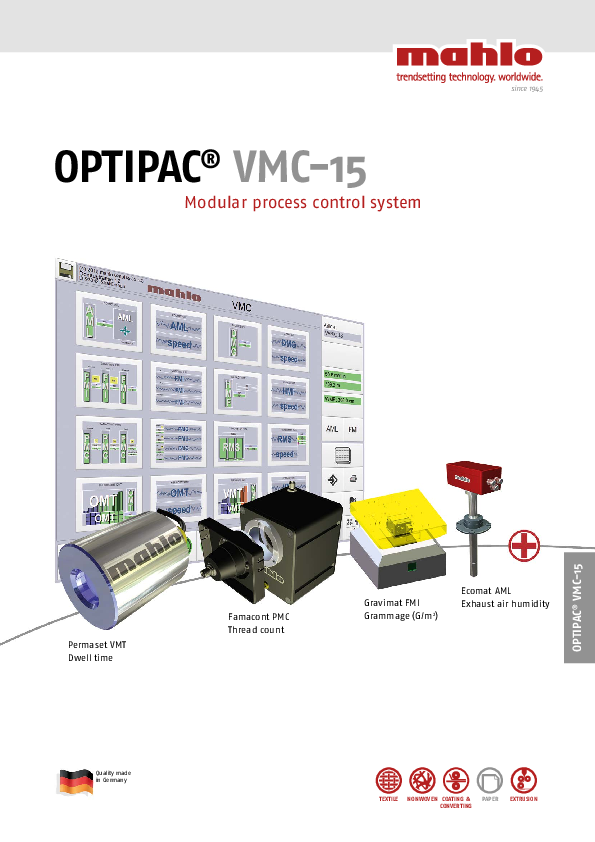

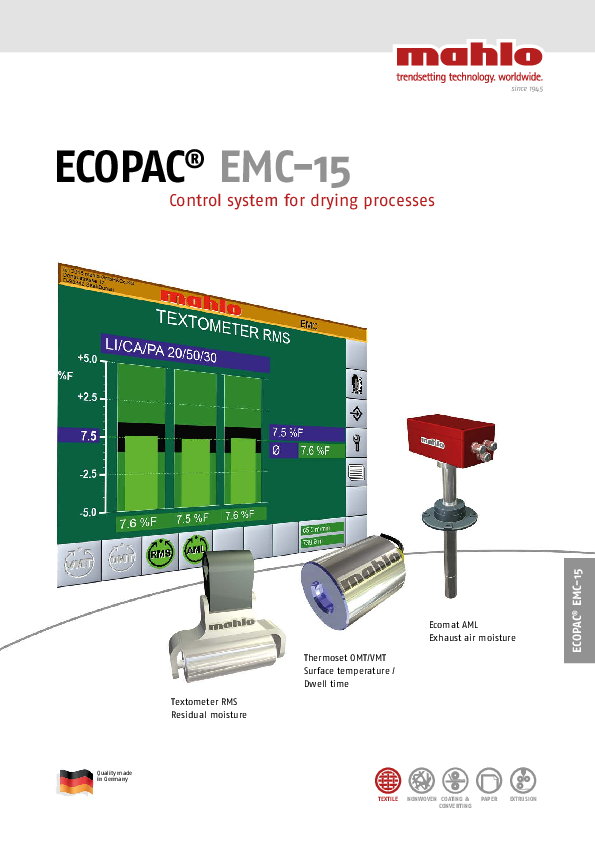

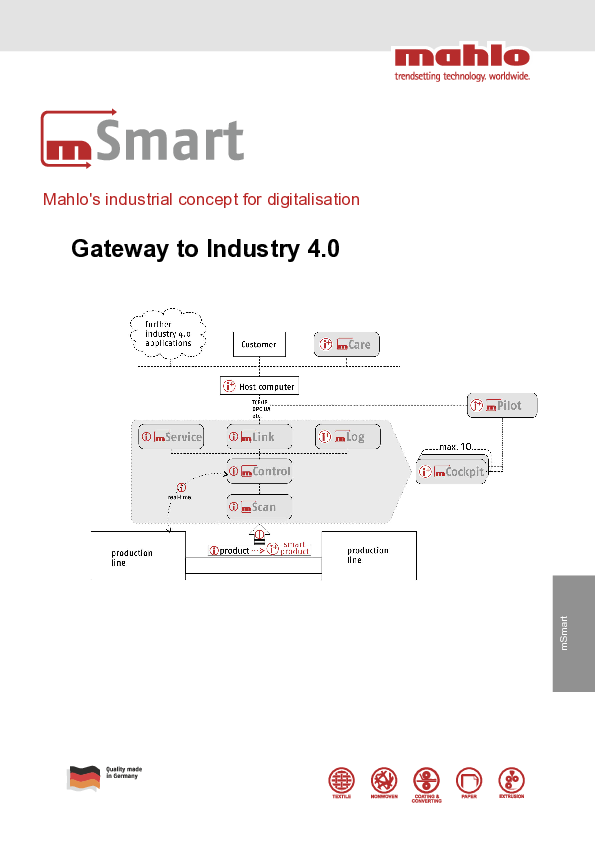

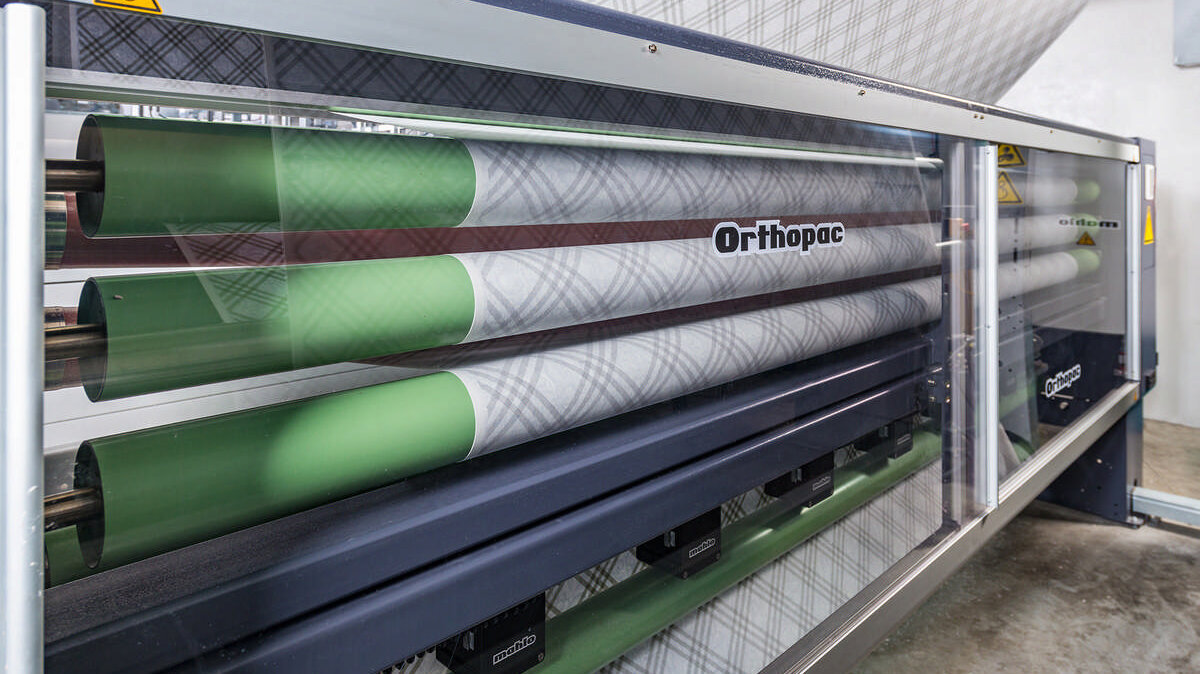

Pezzoli relies on Mahlo technology for straight-thread fabrics as well as process control and quality control during the finishing processes on the stenter frame. In the installation shown, a combination of Orthopac weft straighteners at the inlet and outlet of the stenter frame ensures perfect straightening results. For the best printing results, the Patcontrol system also monitors the pattern repeat and pattern distortion. The parameters in the stenter frame - dwell time, exhaust air moisture, residual moisture, fabric width - are monitored by the Optipac process control system.

Images courtesy of Stamperia Pezzoli, Italy

Stenter frame with Orthopac weft straightener at the inlet and outlet. A Patcontrol PCS also scans pattern distortions. The Optipac process control controls the dwell time, exhaust air and residual moisture.

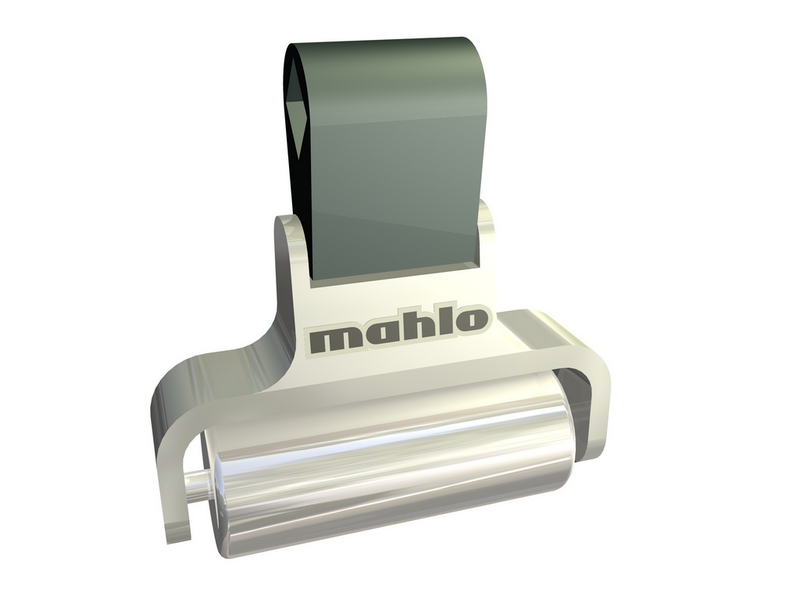

The Ortopac RVMC uses skew rollers and bow rollers to correct skew and bow distortions in the fabric.

The residual moisture content is determined by the electrical conductivity of the fabric.

Residual moisture: Textometer RMS

The useful increase of the residual moisture of the product from 4-8% prevents overdrying and results in:

- Increased productivity speed by 10%

- Drop of production costs per running metre by 11%

- Drop of energy consumption by 4%

ROI calculator residual moisture measurement

Test with your own values

Enter the values for your goods in the column "Without residual moisture control".

All values except residual moisture are automatically transferred to the column "With residual moisture control" and cannot be changed there (as they remain the same).

You can only change the value of the residual moisture. With control, a higher residual moisture is possible that corresponds exactly to the setpoint in the final state.

Find out how much you save if you can produce your goods with a higher or exactly the right residual moisture.

Usual values range between 6 and 10%.

Get your personal offer now

Send your calculations to our experts and start saving money!

GDPR notice

Data safety is important to us

In accordance with the General Data Protection Regulation (GDPR), we will send you an confirmation email to ensure that this request actually comes from you.

Please confirm your request with the emedded link in that email. After that we can process your request immediately.

If you do not receive an email, please also check your spam folder!

Textometer RMS

Control of residual moisture

Measuring electrical conductivity

Moisture retention (residual moisture) is an important criterion in terms of later finishing, finished product scrap and energy optimizing. Electrodes determine the residual moisture at the outlet of the dryer utilising electrical conductivity measurement.

The dryer speed is automatically adjusted until the desired degree of drying has been reached. Many different electrodes are available for a wide variety of applications.

Product Highlights

- Measurement of even low percentages of residual moisture

- Excellent repeatability

- Maintenance and trouble-free

Customer benefits

- Higher productivity and better quality

- Optimal residual moisture for further processing

- Optimal use of drying capacity

One of the most important criteria in drying processes is the product moisture. The correct residual moisture of the product determines the economical factor in each drying procedure as well as the quality of the product and/or later finishing to a great extent.

Overdrying of the textile usually has a very negative effect on product appearance and feel. Residual moisture below the hygroscopic moisture balance results in weight loss and thus lower profits. If the textile is overdried in the stenter the drier speed drops significantly: an enormous reduction of the dryer capacity.

- Textile finishing

- Stenter frame