Flat bed printing & Rotary printing

Stamperia Pezzoli offers printing and finishing services for textiles for more than 35 years, maintaining the highest quality standards in every step of the manufacturing process and ensuring a highly competitive service in terms of technology and styling. Stamperia Pezzoli's finished textiles are used worldwide mainly for furniture and linen in households, hotels and hospitals. They are also used in the shipping industry and in the outdoor sector.

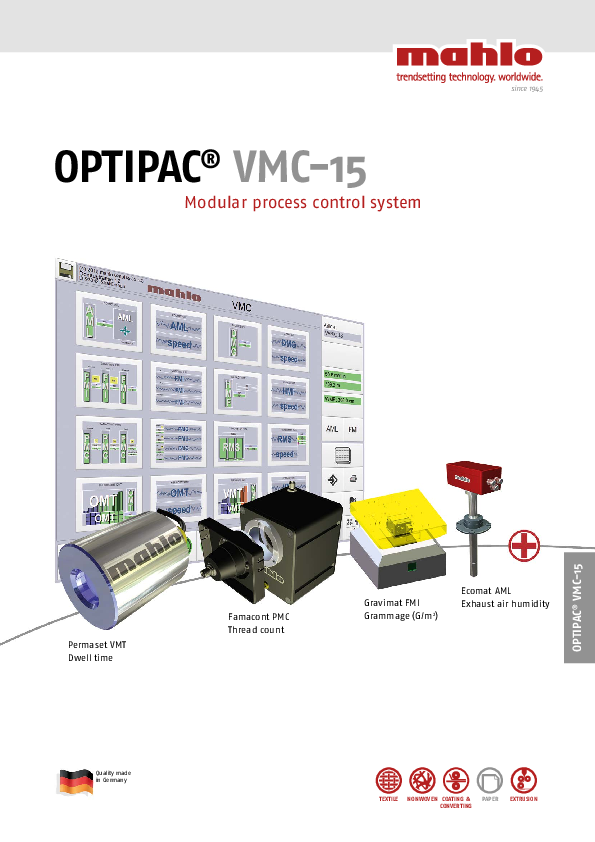

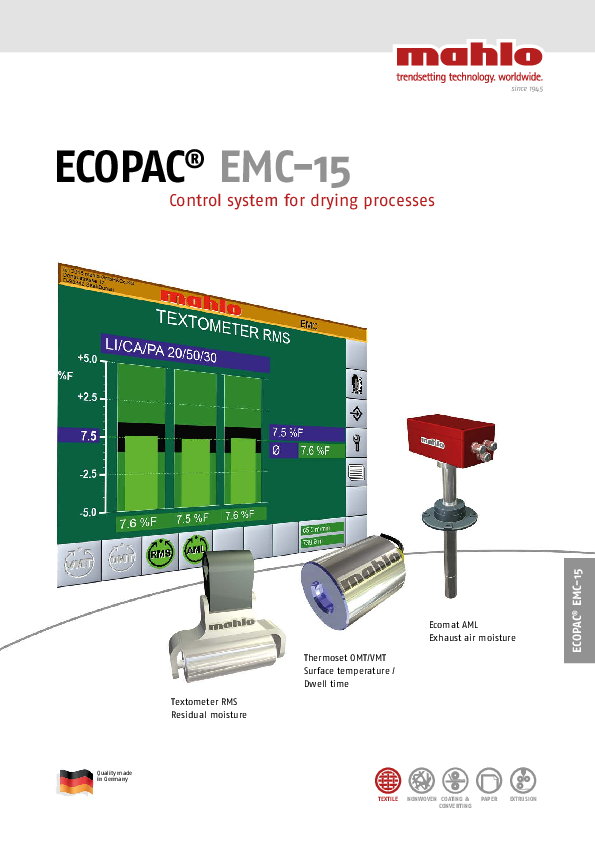

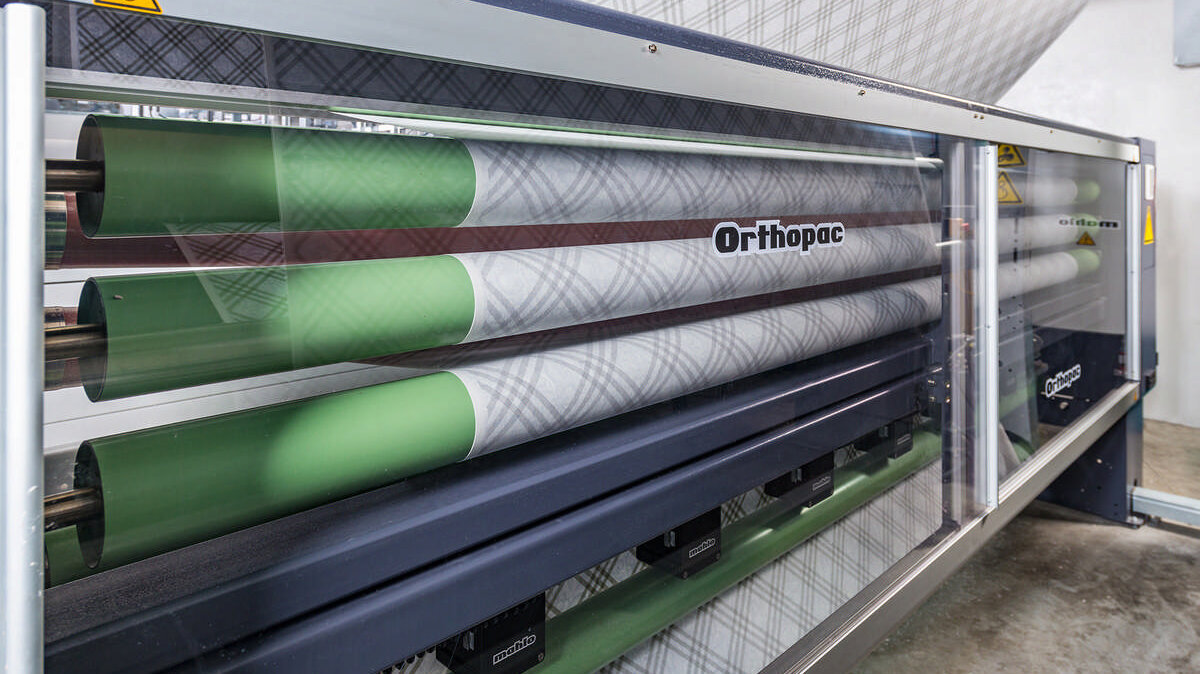

Pezzoli relies on Mahlo technology for straight-thread fabrics as well as process control and quality control during the finishing processes on the stenter frame. In the installation shown, a combination of Orthopac weft straighteners at the inlet and outlet of the stenter frame ensures perfect straightening results. For the best printing results, the Patcontrol system also monitors the pattern repeat and pattern distortion. The parameters in the stenter frame - dwell time, exhaust air moisture, residual moisture, fabric width - are monitored by the Optipac process control system.

Images courtesy of Stamperia Pezzoli, Italy

Stenter frame with Orthopac weft straightener at the inlet and outlet. A Patcontrol PCS also scans pattern distortions. The Optipac process control controls the dwell time, exhaust air and residual moisture.

The Ortopac RVMC uses skew rollers and bow rollers to correct skew and bow distortions in the fabric.

Permaset VMT

Control of dwell time and fixing time

Infrared pyrometer

To determine the dwell time or fixing time for a desired product temperature, the surface temperature of the product is measured without contact at several locations in the dryer using high-temperature resistant infrared pyrometers. Up 64 sensors are possible. The dryer speed is automatically adapted.

Product Highlights

- Non-contacting product temperature measurement

- High-temperature rated sensors

- Little assembly and maintenance effort

- Self-cleaning sensors

Customer benefits

- Highest repeatability

- Optimal utilisation of the stenter capacity

- Less energy required / yard goods

- Highest process reliability

- Short amortisation time

- Elimination of safety margins

Stenter control made easy

Without knowledge of what’s happening during a fixing, thermo-isolating, condensing or gelling process in the drying chambers, the stenter has to be looked at like a block box. The user had only his own experience to fall back on. Settings for circulation temperature and stenter speed have to be determined empirically. To ensure adequate process reliability most stenters are operated with large safety margins regarding possible speeds. They are therefore far away from optimal utilisation of machine capacity and energy invested.

In many processes knowledge of what happens in the stenter is not only an economic question. The achievable product quality also depends largely on the suitable temperature and dwell time.

With thermo-fixing of textiles with Lycra portions excessive product temperatures may, for example, cause the Lycra portion to loose elasticity. This would mean significant quality reduction.

To ensure repeatable processes, the use of appropriate measuring equipment in the drier chambers is essential.

| HP-270-0 | Standard version |

| HP-270-1 | With sensor extension and mounted control box |

| HP-270-2 | With mounting plate for the sensor |

| HP-270-3 | With sensor extension and remote control box |