Diecontrol APC Pro

Automatic Extrusion Die Control System

Automatic control of thermal diebolts of extrusion dies

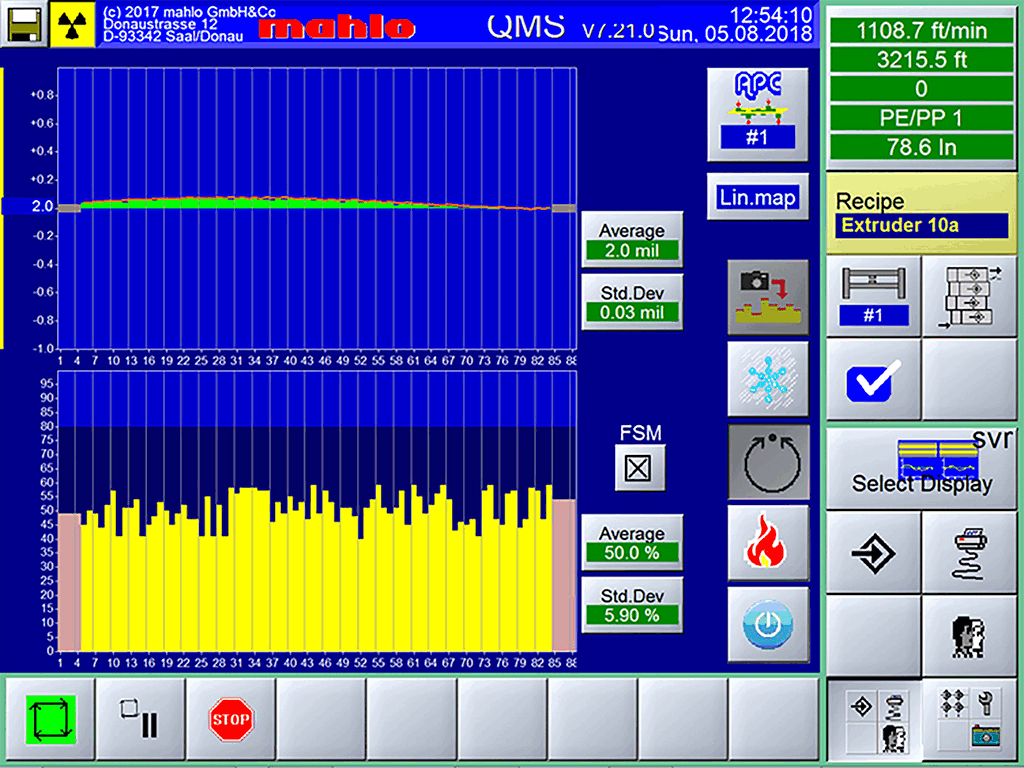

The DieControl APC Pro automatically controls thermal bolts of extrusion dies according to the earlier measured cross-section profile of the material. This results in uniformly thick films, sheets or coatings even with fluctuations in the feed, material change or when starting the system.

The automatic control and the extrusion close to the set point also achieve considerable material savings and quality improvement.

Product Highlights

- Exceedingly short recovery times by using optimised “feed-forward” control algorithms

- Modular construction facilitates maintenance and expandability

- Automatic improvement of power-factor by varying the switching time points

- Innovative features such as predictive Neck-In Compensation and Edge-Bead Control

Customer benefits

- Fully automatic reduction of repetitive errors in crosssheet thickness (coating)

- Considerable savings in raw material thanks to a minimum of set-point errors

- A marked improvement in the quality of the end product

- Instant control ensures a minimum of lost production when changing batches

- Automatic reduction of operator errors thanks to closed-loop control

The uniform thickness of the film is a decisive quality feature.

Extrusion and extrusion coating

Plastic sheets or films are produced by extrusion. By an extruder the plastic melt is forced through an extrusion die which determines the final shape of the sheets. Also in the extrusion coating, extrusion dies are used to apply the liquid coating to the substrate.

The uniform thickness of the extruded material is controlled by a flexible lip at the exit of the die. This lip can be changed by many individual bolts. Thus, the thickness can be precisely adjusted in numerous, short segments. This is automated via so-called thermo-bolts, which change their length according to the applied temperature.

The DieControl APC Pro thermal die controller can be used with all the usual extrusion dies which can regulate via thermal die elements the amount of coating applied cross-sheet.

These dies are used chiefly for film extrusion (cast film) and extrusion coating. They can also be used on special applications such as the manufacture via a coating process of special membranes on high-precision, guided steel bands.

Regardless of the application, the DieControl APC Pro is used to compensate for set-point errors in the thickness or basis weight of the product, specifically in those segments of the extrusion die in which these errors occur.

The DieControl APC Pro is usually coupled to one of Mahlo's Qualiscan QMS sensing systems, which continuously detects these errors across the entire width of the sheet, and transmits this profiling data to the DieControl APC Pro via a data bus link.

Documents