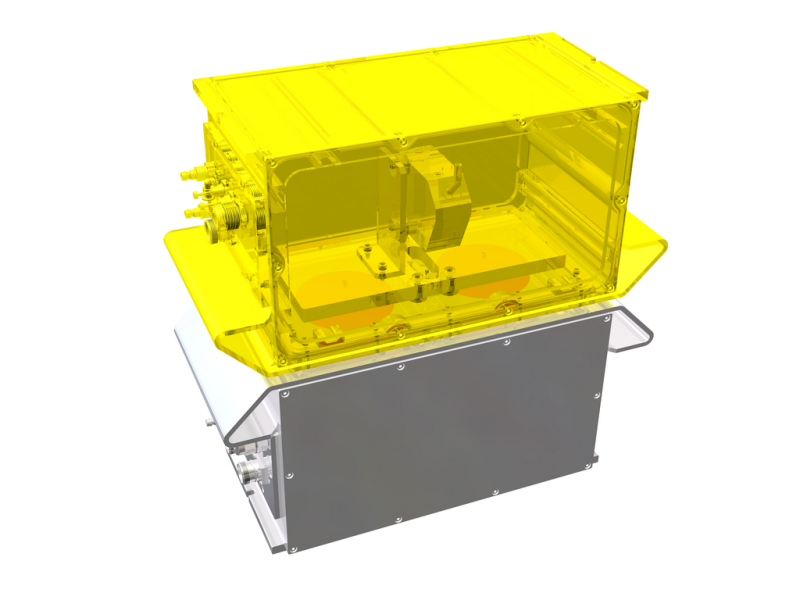

Calipro DML

Measurement of thickness (contactless)

Laser triangulation

The Calipro DML optical system uses laser triangulation online to measure the thickness or coating thickness of various materials with the highest accuracy.

Product Highlights

- Non-contact, non-destructive and ultra-precise measurement online of product thickness

- Available in several configurations to suit various requirements in terms of accuracy

- Can gauge either at one side against a reference roller or on both sides

Customer benefits

- Determines the thickness of a web or sheet directly without reference to product density

- Since the gauge is able to traverse, it indicates the thickness of the product from edge to edge

- Non-contact measurement has no adverse effect on either product quality or the manufacturing process

- Paper and cardboard industry

- Nonwoven sector

- Manufacturing of PVC flooring

- Calendered or extruded plastic webs and sheets

- Manufacturing of artificial leather

In principle, the two-sided, non-contact, laser-type thickness gauge can be used to monitor virtually any product in web or sheet form. Successful applications for this technique can be found in the paper and cardboard industry, nonwoven sector, plants manufacturing PVC flooring or other calendered or extruded plastic webs and sheets, and in the manufacture of artificial leather.

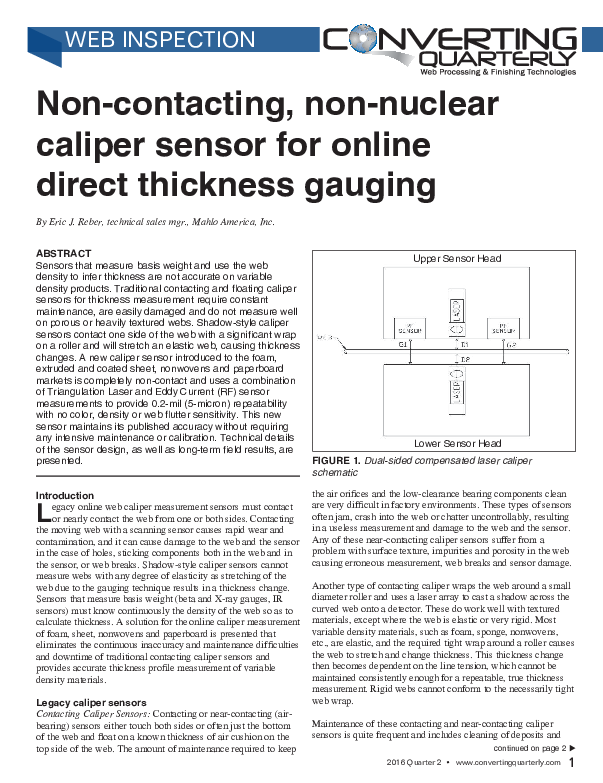

Either one or two laser-triangulation sensors determine the exact distance between the gauging sensor(s) and product surface, either from one or both sides.

Depending on the arrangement, an additional sensor, usually a high-precision eddy-current sensor, determines either the distance between the two gauging sensors or distance between the one sensor and a reference roller.

| Specification | Value | Unit | |

|---|---|---|---|

| Type | DML-S (single sided) | DML-D (double sided) | |

| Measuring range 1 | 20 - 80 | 10 - 100 | mm |

1) depending on variant