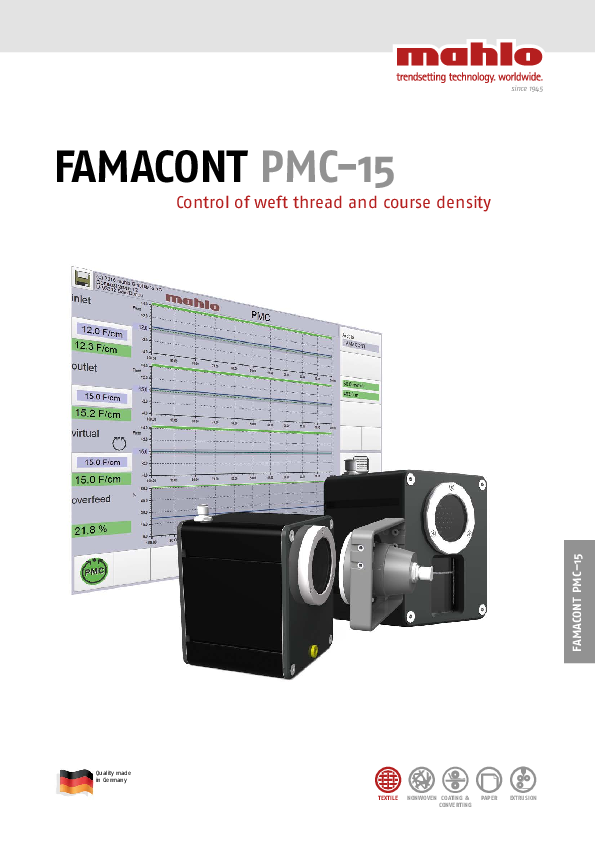

Famacont PMC-15

Control of thread density / course density / basis weight

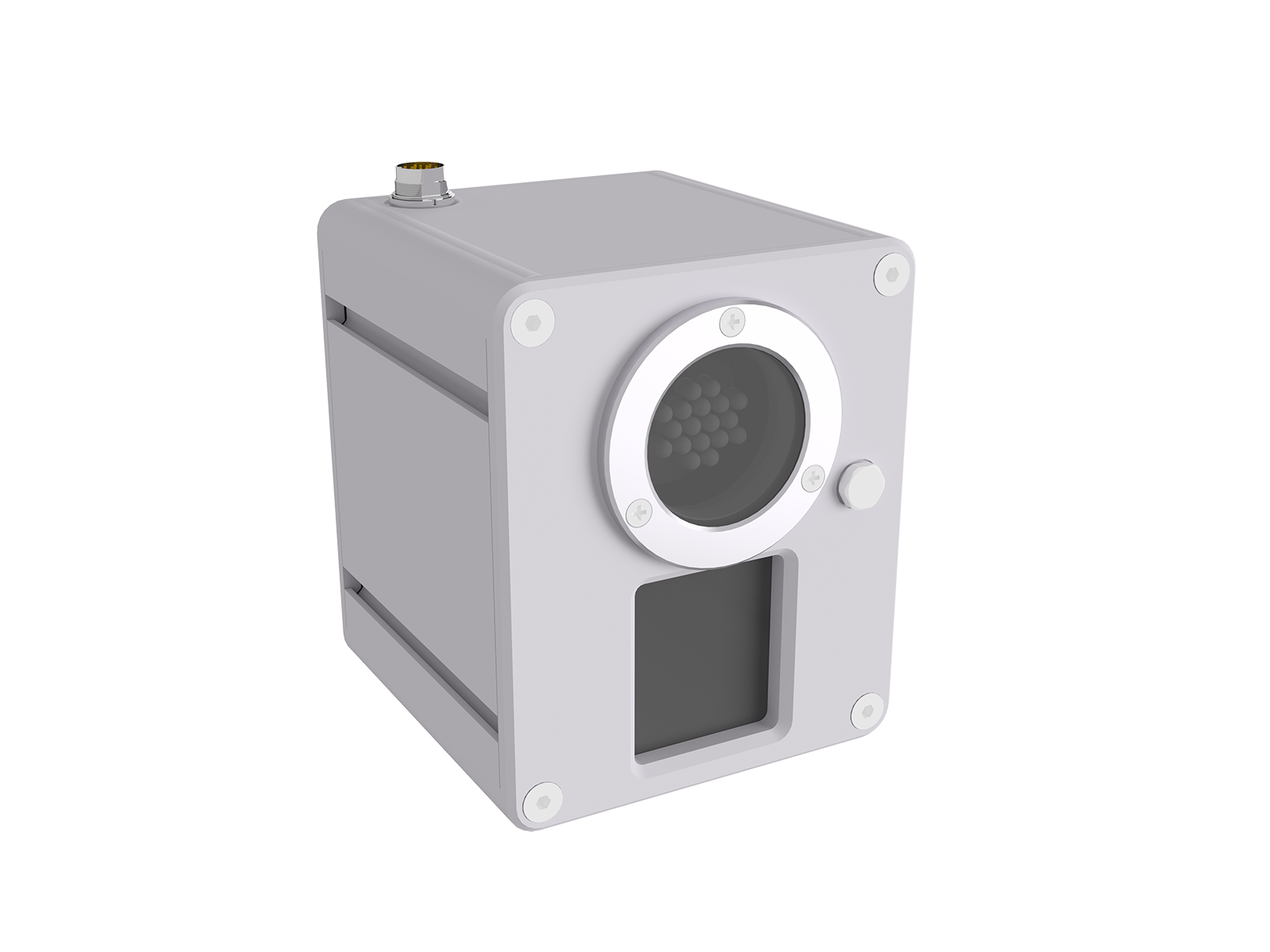

Optolectronic sensor / camera sensor

The Famacont PMC determines the thread density by means of a non-contacting, optoelectronic or imaging process. With the optoelectronic process individual threads or courses pass the sensor and are projected onto the photocell using a precision optical lens. The resulting frequency is proportional to the thread count.

A high-resolution camera is used with the imaging process. The image is analysed with using suitable software (FFT analysis). Both, the thread count in weft and warp direction can be determined here with maximum precision.

Product Highlights

- Non-contacting and continuous

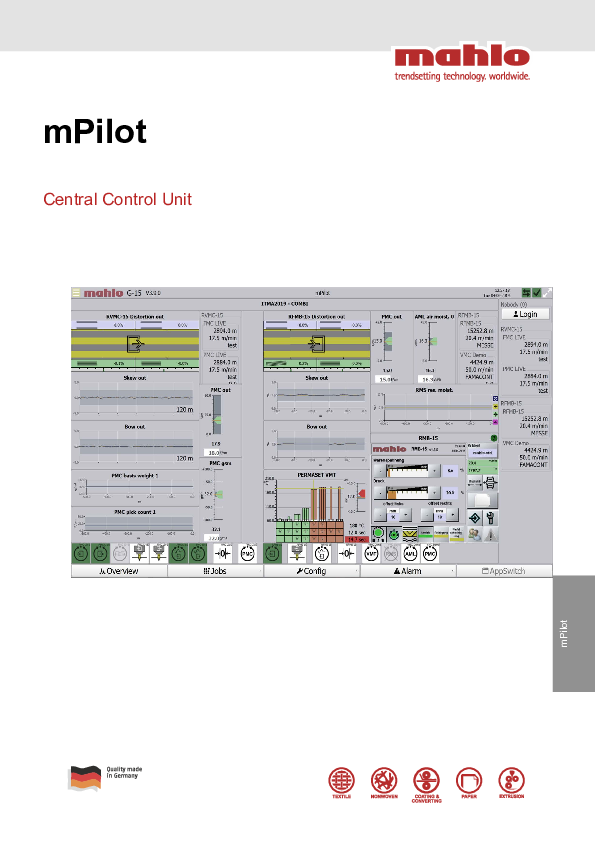

- Determines the thread or knit density with the greatest accuracy using digital signal processing

- With ”smart” feed forward control algorithm

- Universal application

Customer benefits

- High repeatability

- Consistent residual shrinkage values

- Homogeneous product appearance

- Documentation of product quality

- Short amortisation times

Continuous exact scanning of the weft thread or course density is an important factor for quality optimisation when finishing textile products.

In order to achieve homogeneous product density and increased production yield, the Famacont PMC controls the over-feed direction fully automatically.

- Stenter frames

- Shrinking machines

- Compacting machines

The Famacont PMC is a reliable instrument for non-contacting, inprocess determination of the weft thread / course count. Essential parameters such as weight, stretch / shrinkage are thus monitored and controlled. The Famacont PMC is an important tool for the finisher: Quality requirements of the customers are complied with; costs due to rejects and quality loss is minimised. The system is very versatile. Stenter, shrinking and compacting equipment constitute the main application areas.