Nonwoven hygiene products

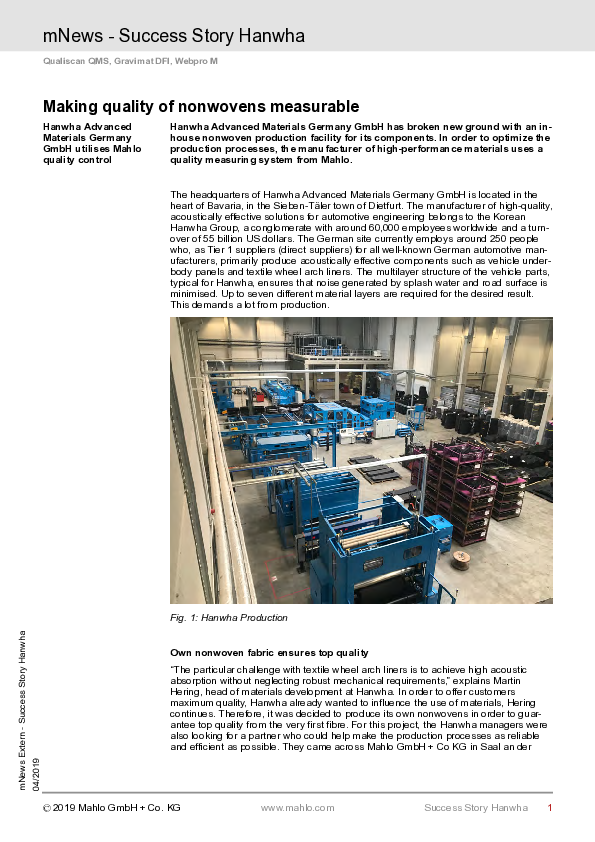

KARWEB NONWOVENS, based in Turkey, is one of the big global players in the sector of hygiene products with more than 270 product types made from nonwoven fabric. They export 80 percent of our production to 36 countries, like America, England and Italy. At their Spunlace plant, they can produce protective products against bacterial due to sophisticated technologies like Ozone Threatment and UV systems.

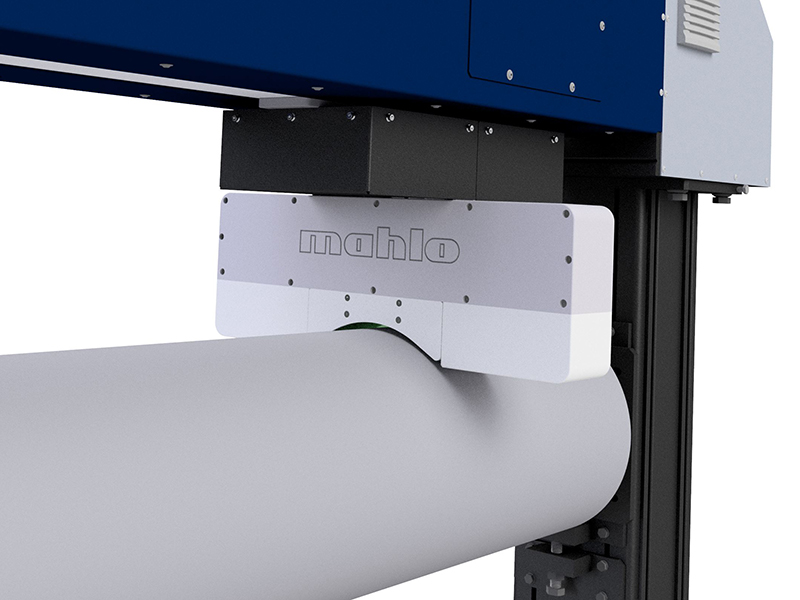

In the quality control process, which is of great importance in the hygiene sector, they rely upon the quality control system Qualiscan QMS-12 from Mahlo. With instant quality detection, they can continuously control the correct component mixture of their fibre products.

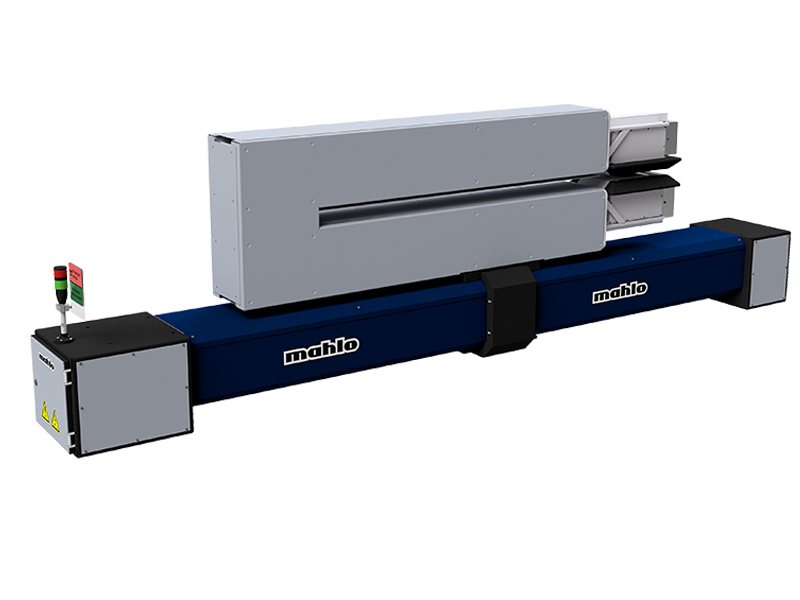

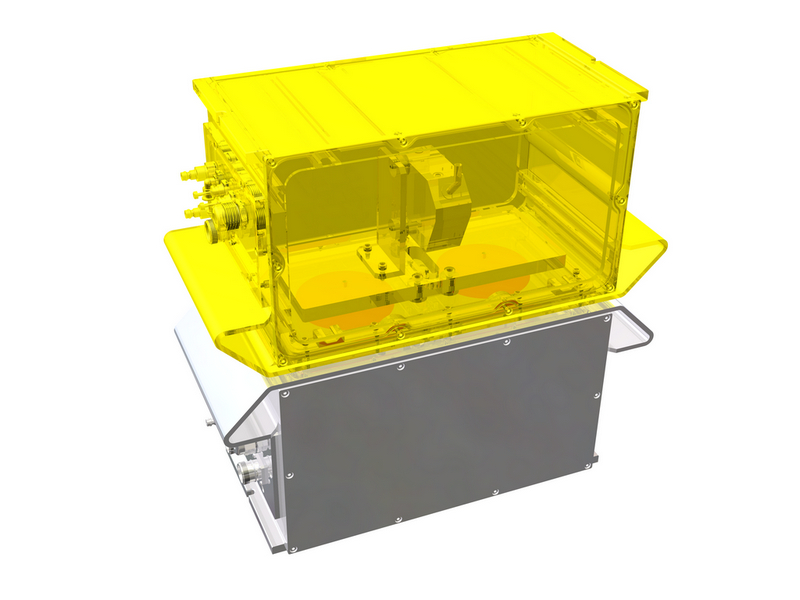

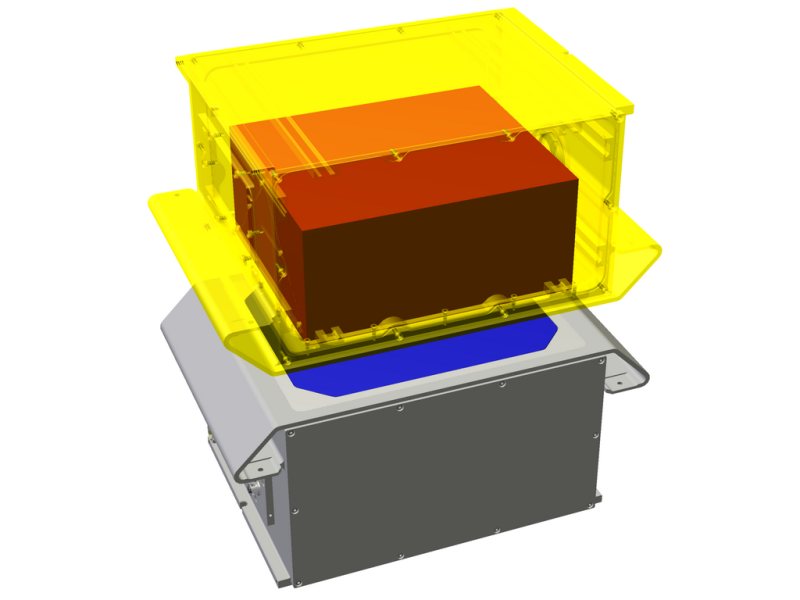

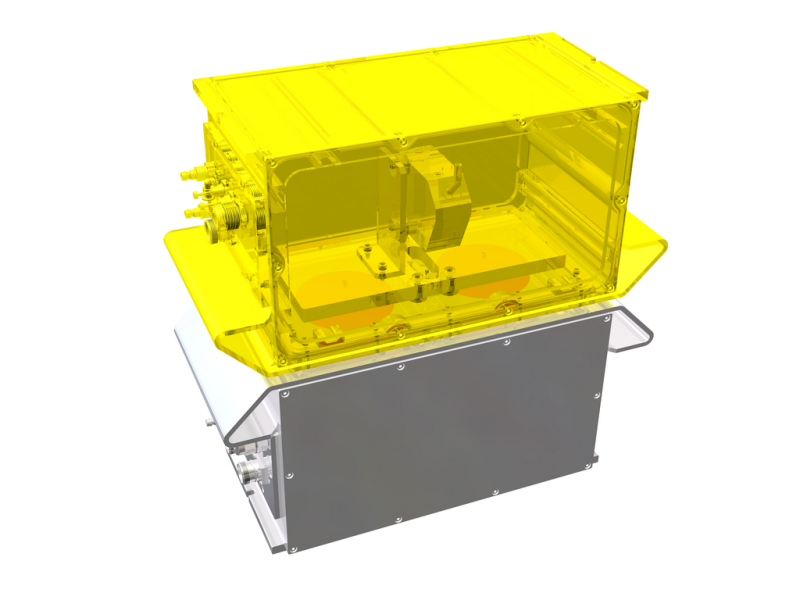

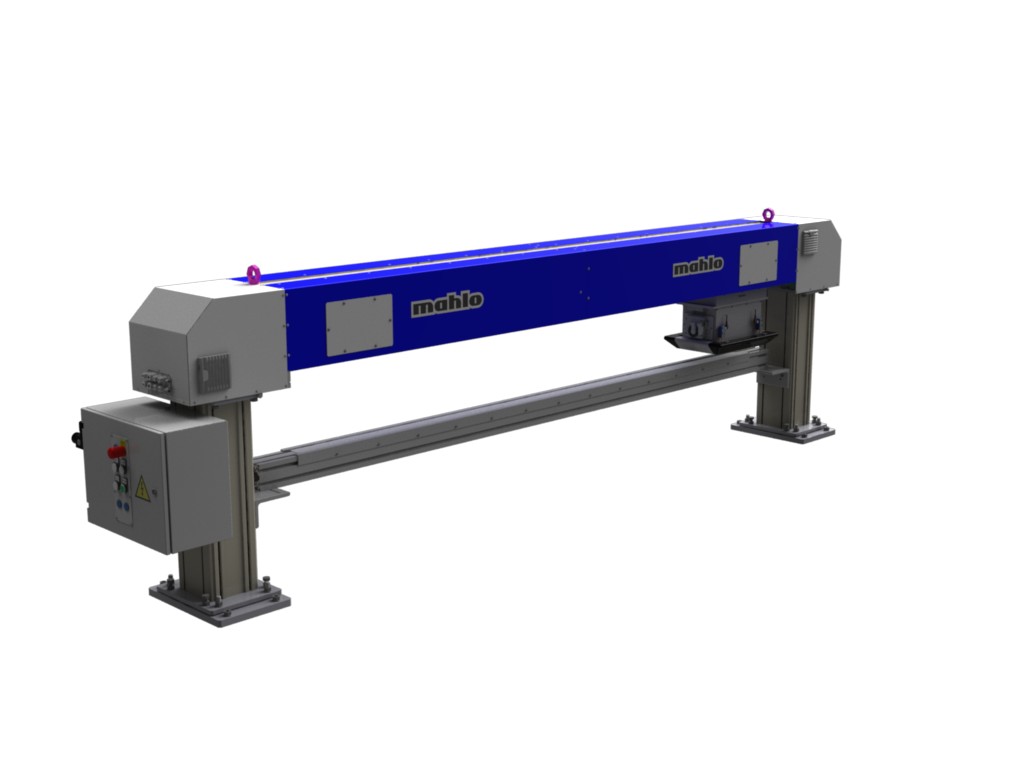

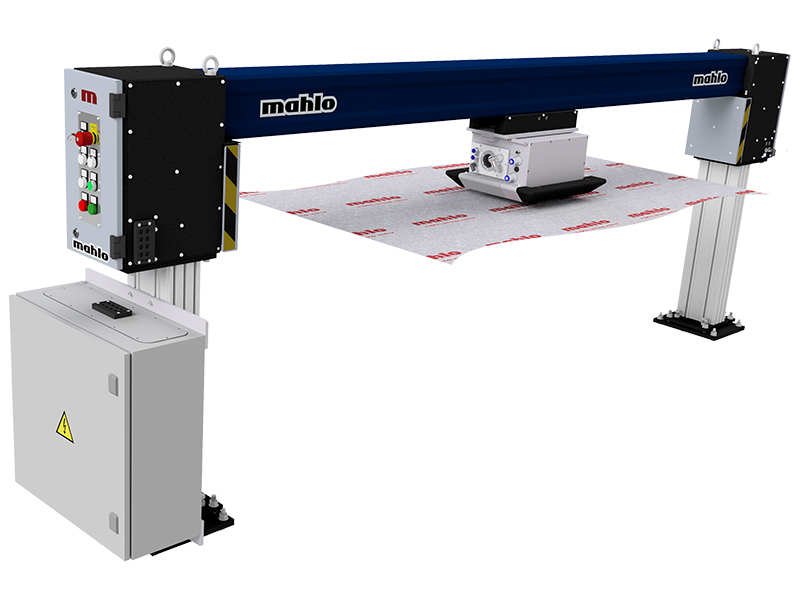

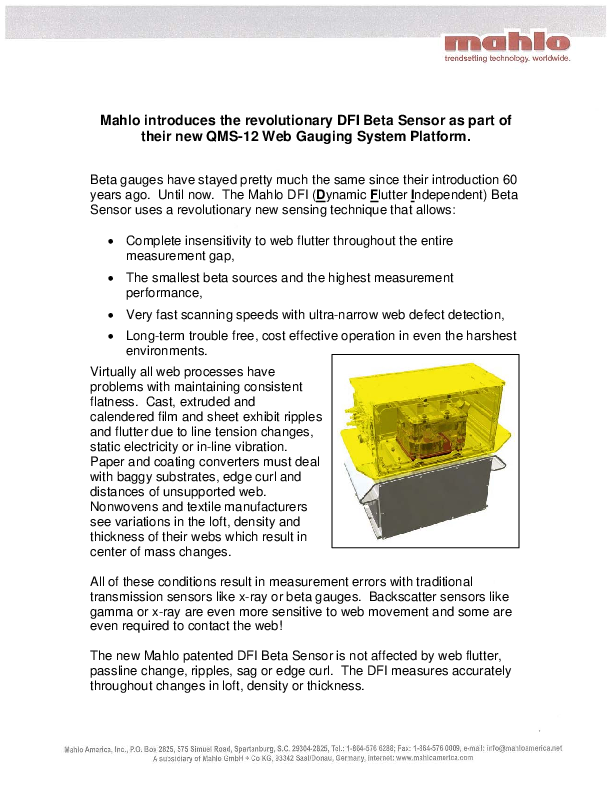

A traversing scanner (o-frame) of type Webpro M with two sensors for simultaneous measurement is used for the task. The infrared sensor Infralot IMF detects the moisture. The Gravimat DFI beta sensor measures the basis weight.

Pictures courtesy of Selçuk İplik, Turkey

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

Accept marketing cookies to enable this video.

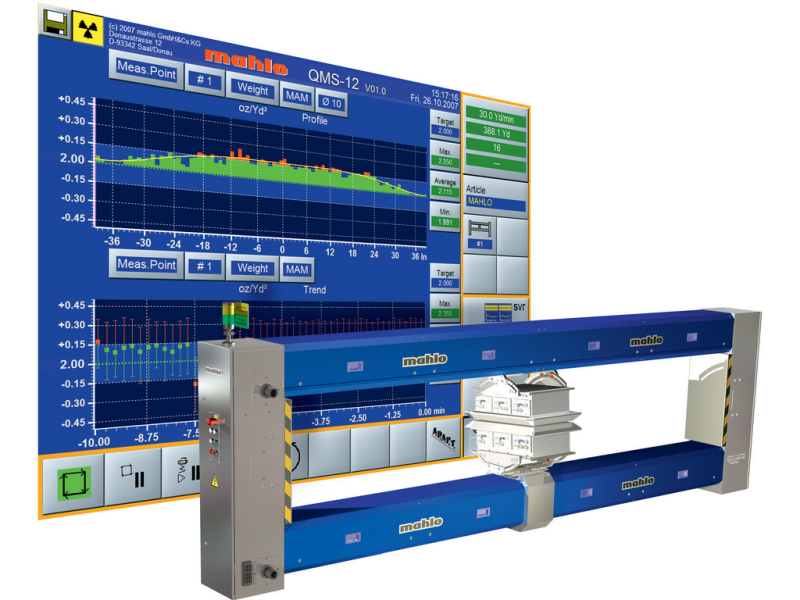

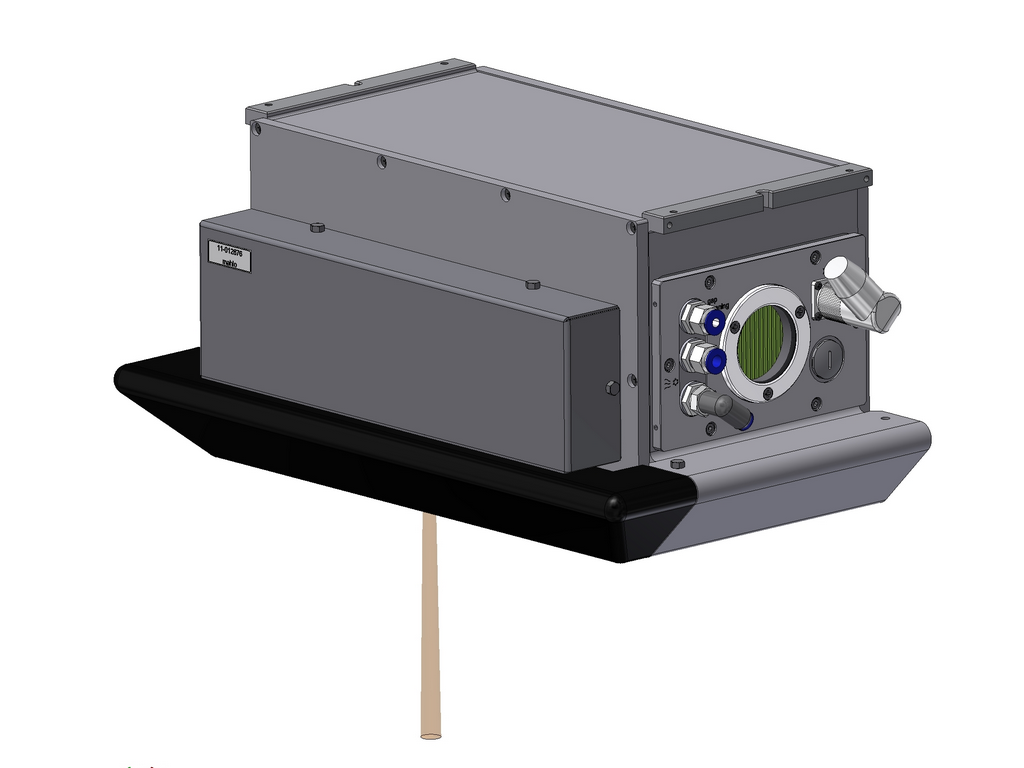

Qualiscan QMS-12

Traversing quality control system

Web process control

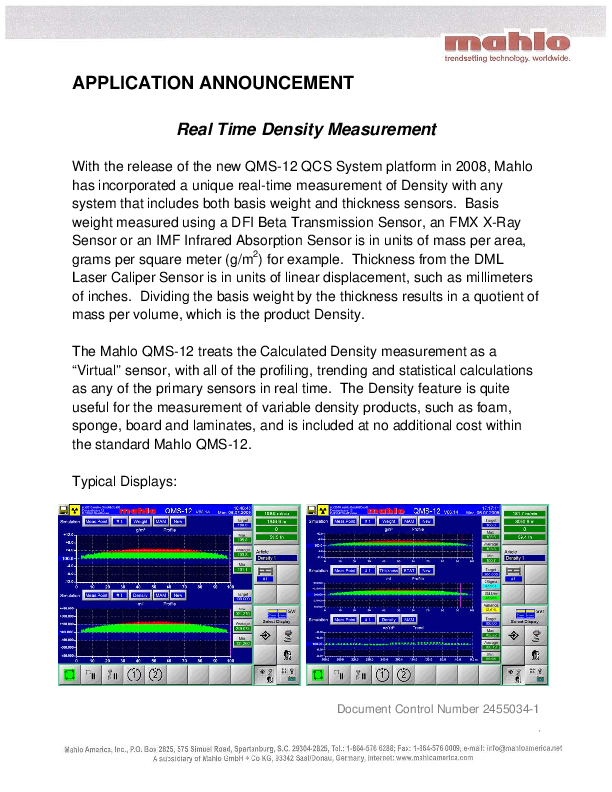

The Qualiscan QMS is a modular system for measuring, logging and controlling critical process parameters over the entire width of the product, including basis weight, coating weight, thickness, moisture etc.

Product Highlights

- Modern construction with intelligent sensors and traversing frames

- Based on industry standard hardened computers running Windows embedded operating system

- Components communicate through digital interfaces

Customer benefits

- Savings in raw materials and/or energy at the manufacturing stage

- Uninterrupted monitoring and logging of actual product quality

- Improvement in product quality, especially in conjunction with control

Sensors

The right tool for every application

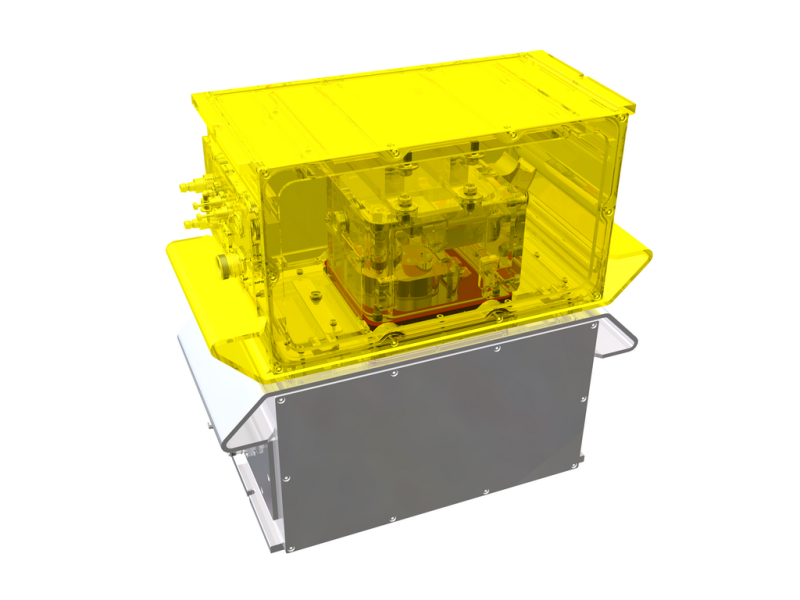

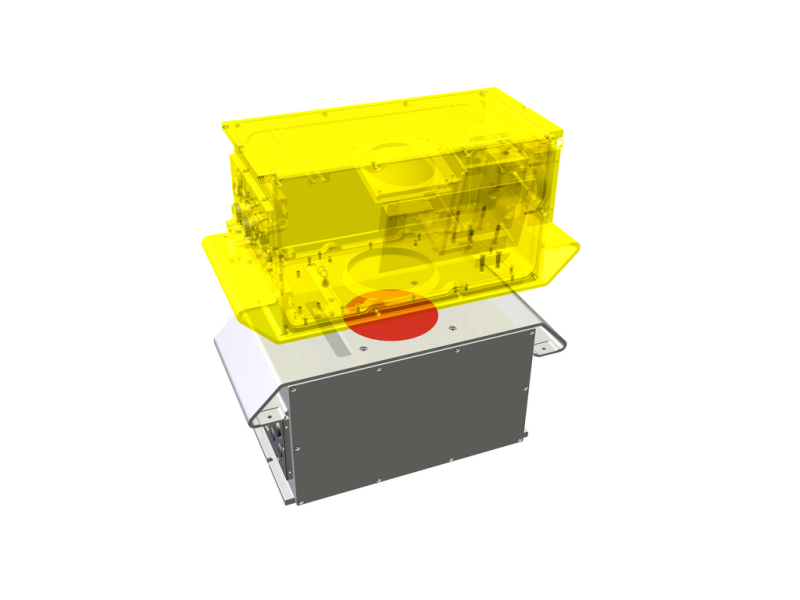

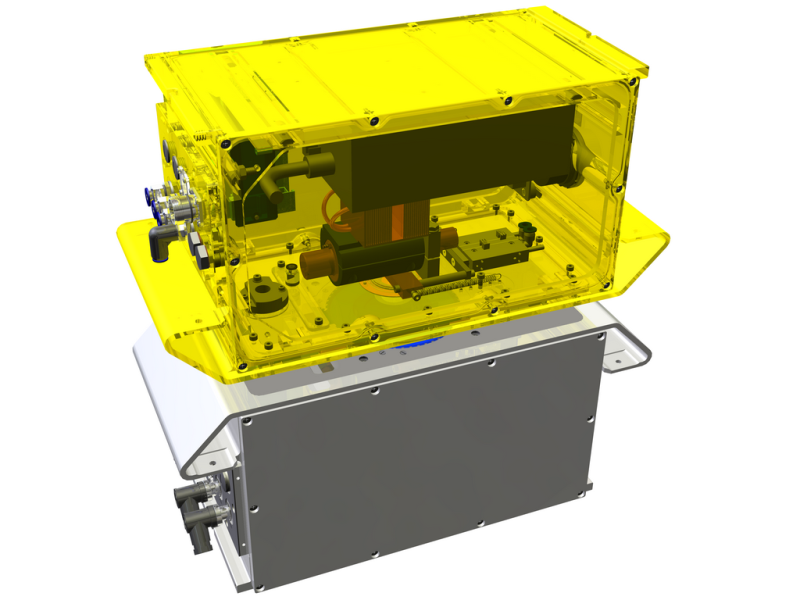

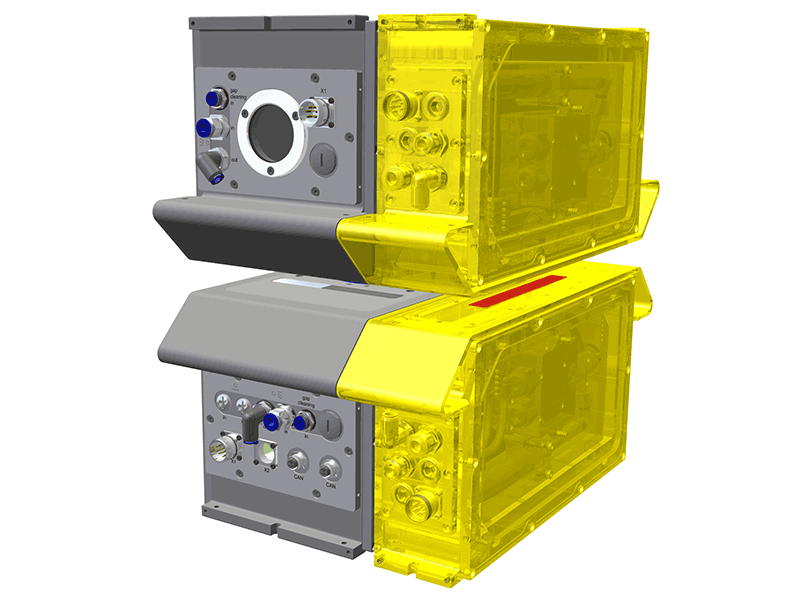

The Qualiscan QMS is a modular system consisting of multiple measuring sensors and measurement frames acting as intelligent nodes on a network. Some frames can run up to five Mahlo sensors at once, continuously, precisely and rapidly across the online product.

The versatile sensors and measuring devices of the Qualiscan QMS series can sense, log and continuously control such parameters as weight per unit area (basis weight), coating weight, thickness and moisture in a variety of web-type products.

Measurement of basis weight (mass per unit area) / thickness /density

Show details

Measurement of basis weight (mass per unit area) / thickness

Show details

Measurement of basis weight (mass per unit area) / thickness / density

Show details

Measurement of basis weight (mass per unit area) / moisture

Show details

Measurement of moisture

Show details

Measurement of web temperature

Show details

Simultaneous measurement of residual moisture (Infralot IMF infrared sensor) and basis weight (Gravimat DFI beta sensor) on running web of spunlace nonwoven fabric

On-line control of key process parameters

The Qualiscan QMS can be used in virtually every industrial sector in which products are produced as a web, or where they are finished (laminated, coated, etc.). The versatile sensors and measuring devices of the Qualiscan QMS series can sense, log and continuously control such parameters as basis weight (weight per unit area), coating weight, thickness and moisture in a variety of web-type products.

- Web process control

- Coating & Converting

- Extrusion

- Nonwoven

- Textile

- Paper

Measuring frames

Universal application

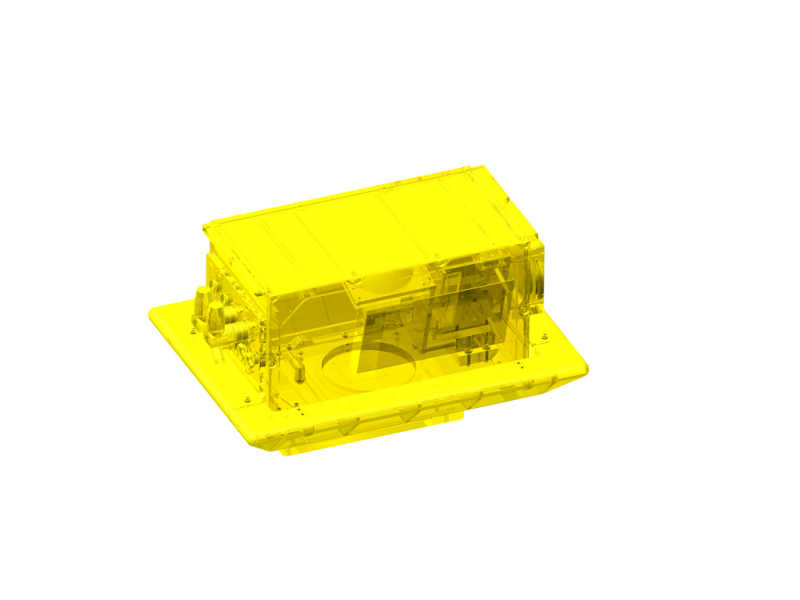

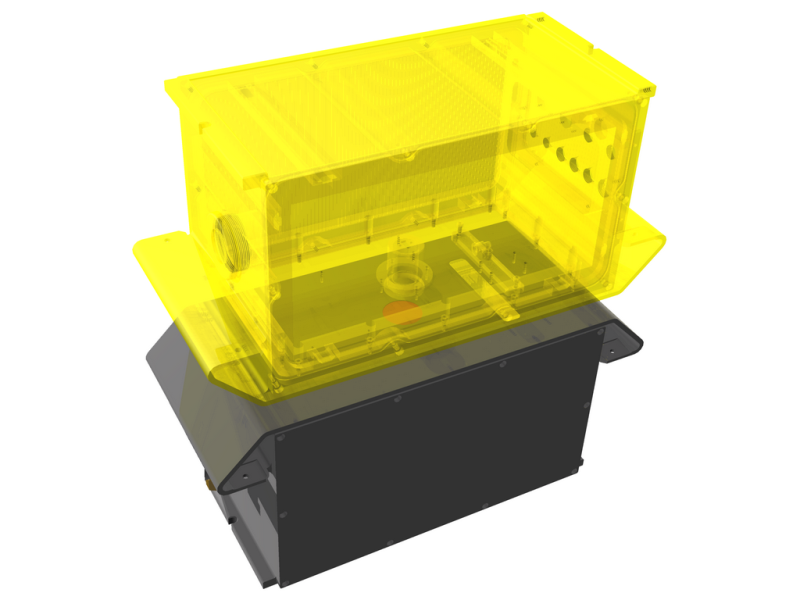

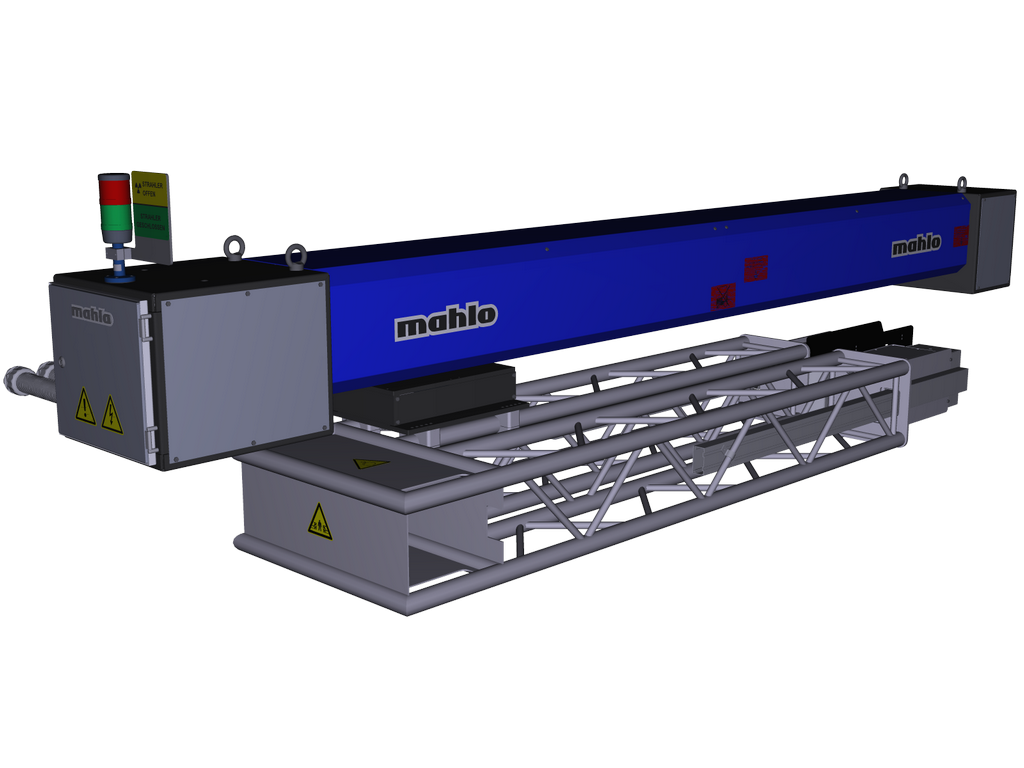

The measuring frame traverses the sensors on-line across the whole product width and provides a cross-machine direction profile of basis weight, thickness or moisture on the display console that is a crosssection of the manufactured product.

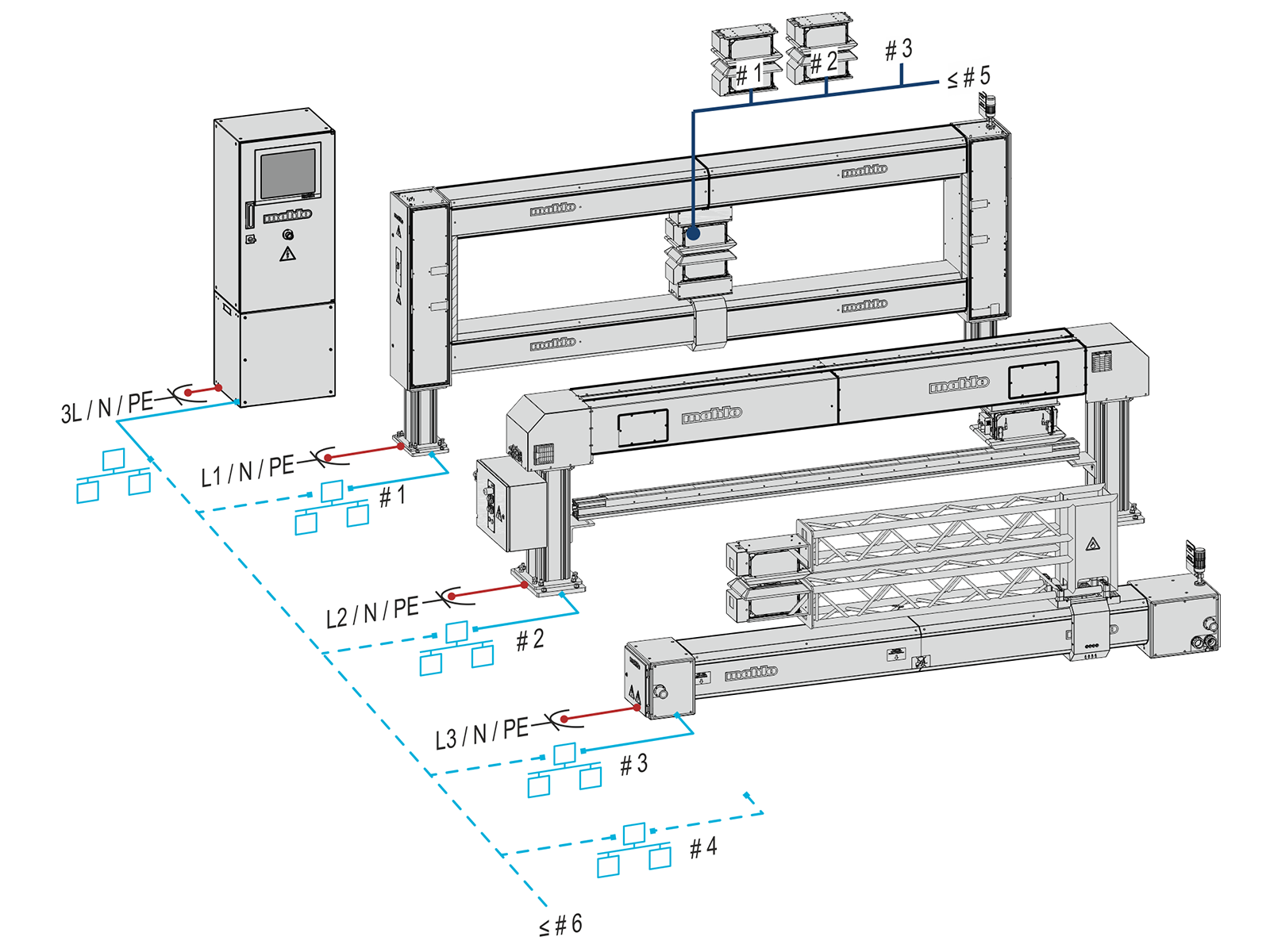

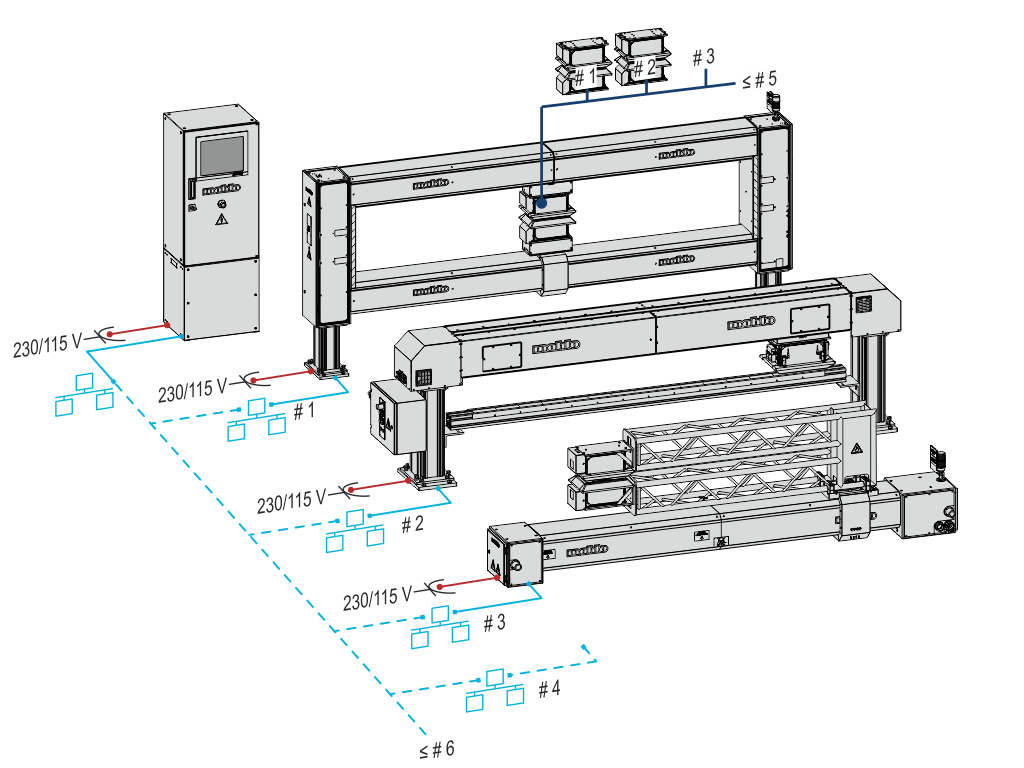

One or more different measuring frames can be connected to a Qualiscan QMS system. Connection is made via a normal network cable, a standard 230/115 V source supplies the power.

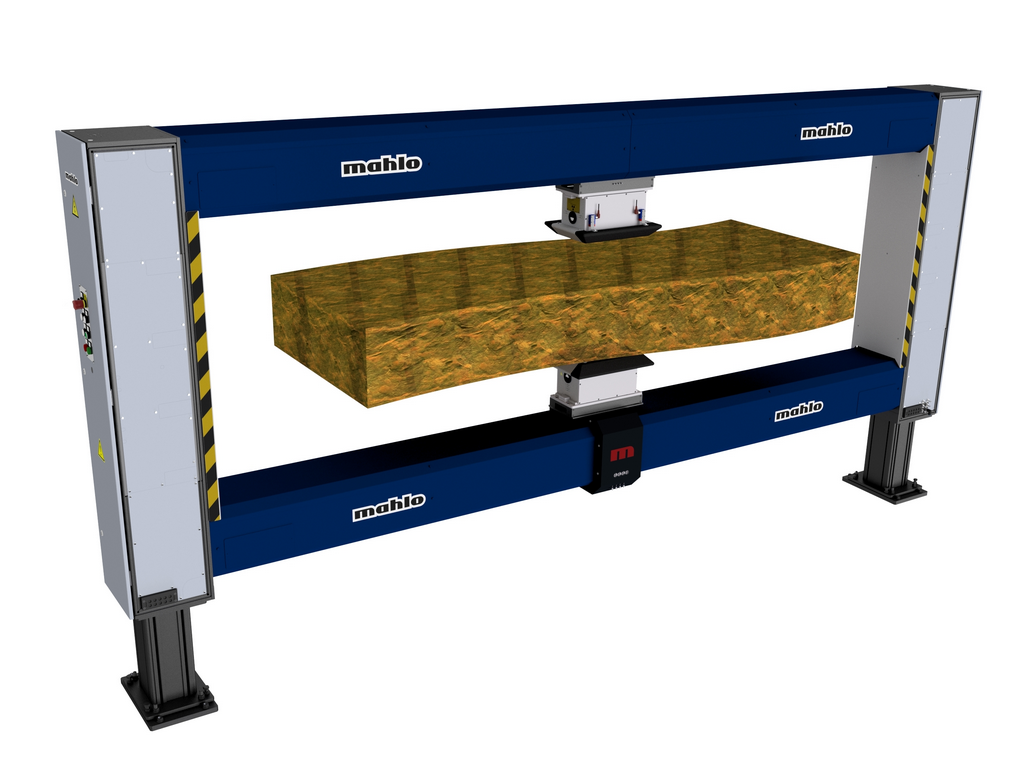

Double-sided measuring frame for large widths and thick webs

Show details

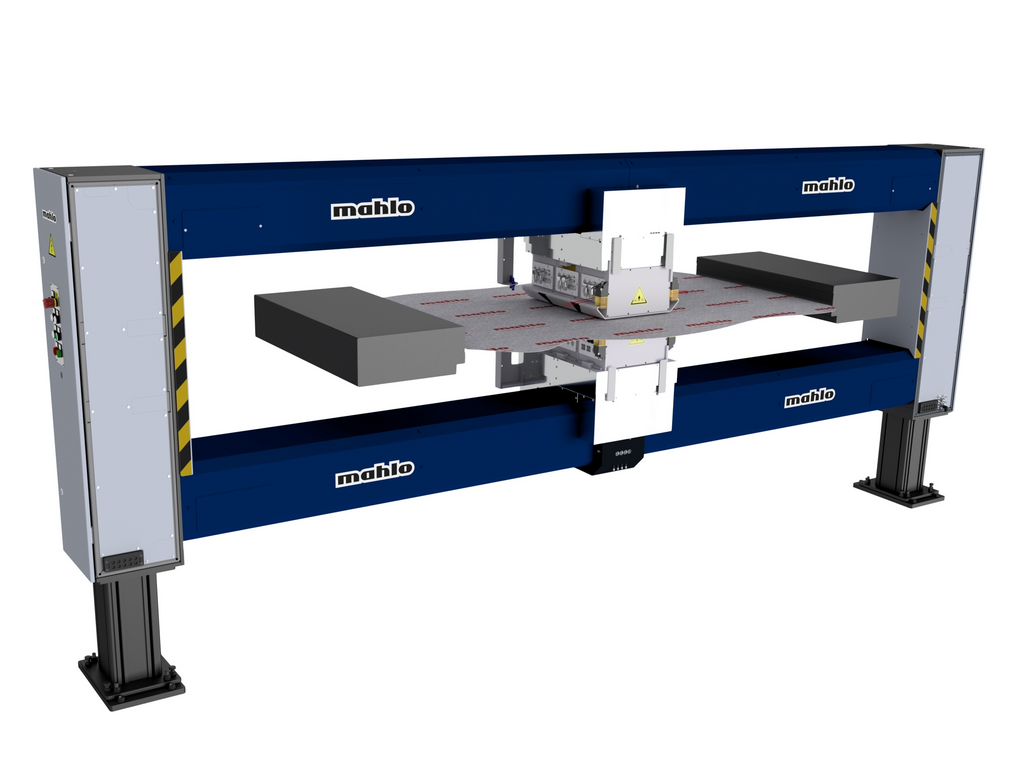

Double-sided measuring frame for normal widths and thick products

Show details

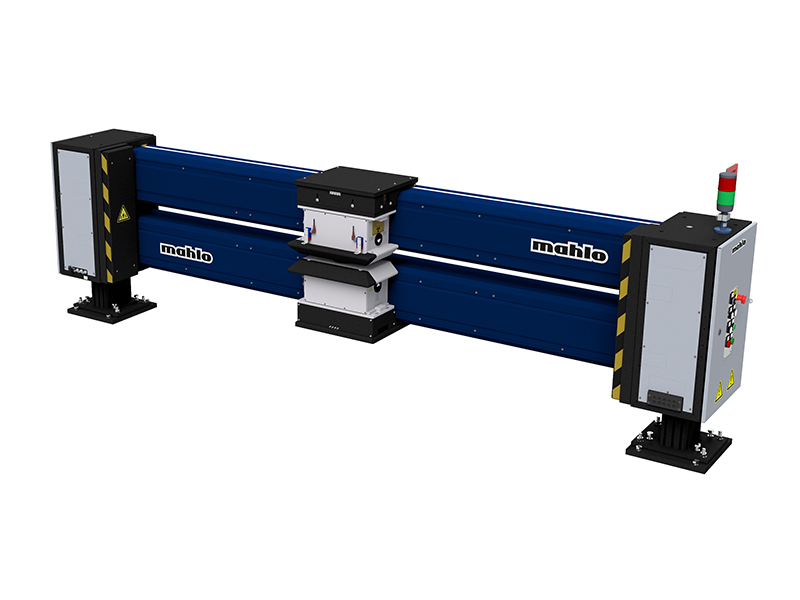

Double sided measuring frame for narrow webs and thick products

Show details

One or more different scanning frames can be connected to a Qualiscan QMS system. Connection is made via a normal network cable, a standard 230/115 V source supplies the power.

Network structure

The Qualiscan QMS is a modular system consisting of multiple measuring sensors and traversing frames acting as intelligent nodes on a network. The individual components are linked through a normal Ethernet cable as found in any office for networking multiple PCs. The network structure facilitates the integration of additional measurement sensors and scanners in the future.

Accessories

Little helpers

Accessories and add-on devices for improving accuracy, quality and performance

Documents